Karthi

New Member

- Joined

- Jul 15, 2018

- Messages

- 2,214

- Likes

- 17,755

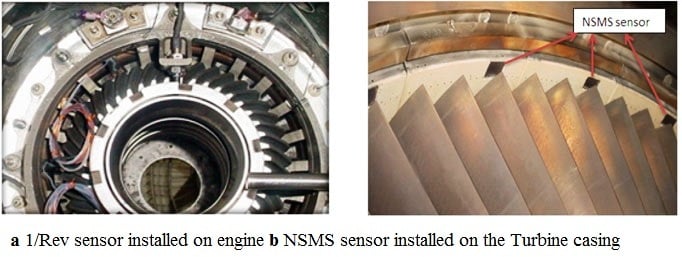

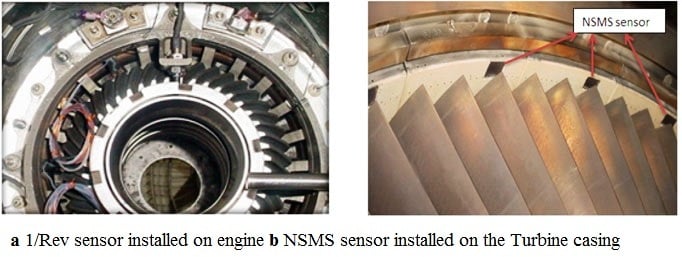

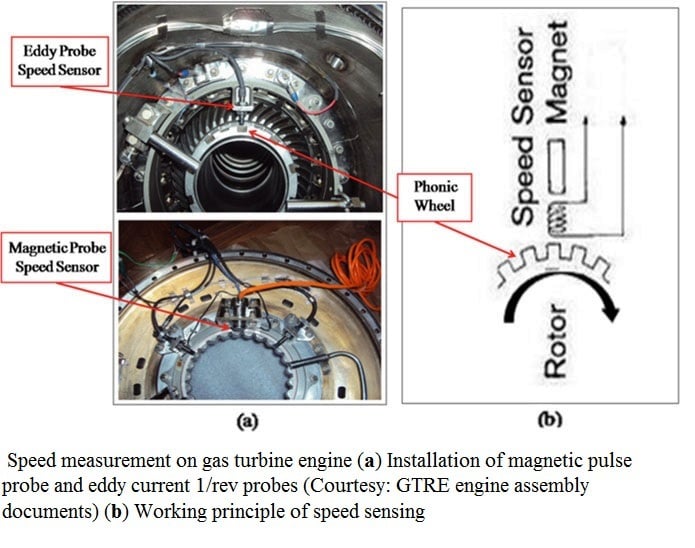

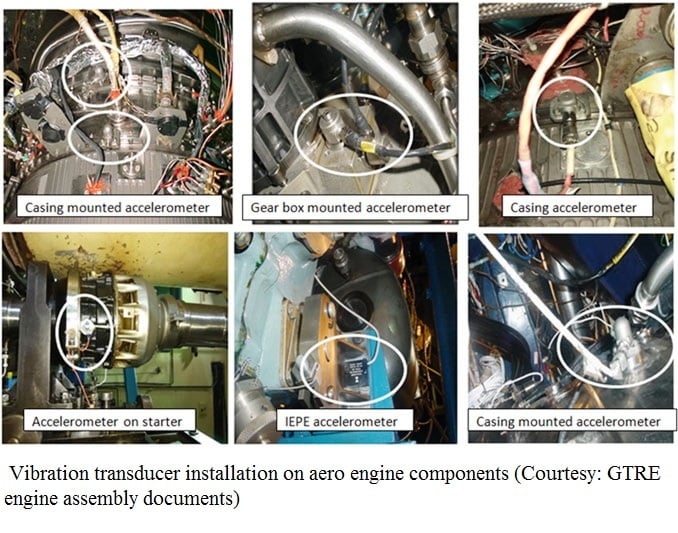

Rotor Blade Vibration Measurement on Aero Gas Turbine Engines

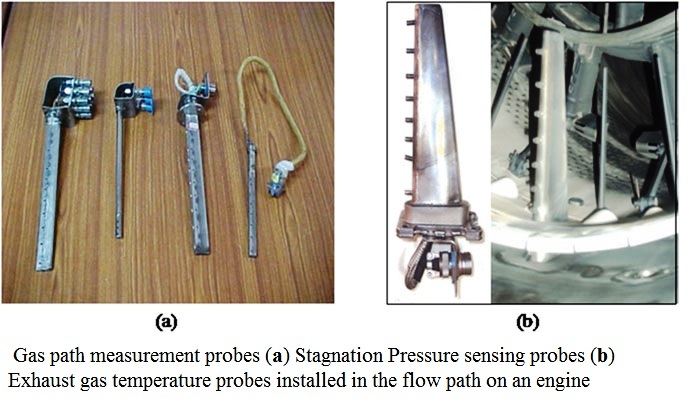

Challenges in Engine Health Monitoring Instrumentation During Developmental Testing of Gas Turbine Engines

//////////////////////////////////////////////////////////////

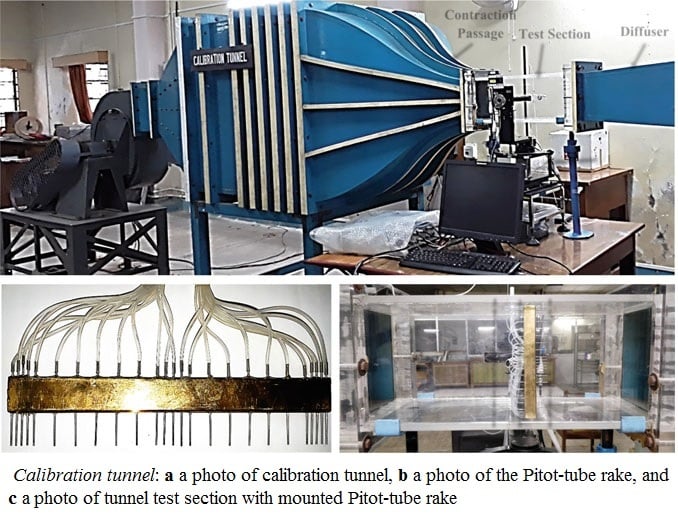

Development of Time-Efficient Multi-hole Pressure Probe Calibration Facility

Challenges in Engine Health Monitoring Instrumentation During Developmental Testing of Gas Turbine Engines

//////////////////////////////////////////////////////////////

Development of Time-Efficient Multi-hole Pressure Probe Calibration Facility