Behind paywall. Pls post full article here.

The Messy Battle to Build the F-35's Next Engine

General Electric and Pratt & Whitney are fighting tooth-and-nail over jet engines—specifically, whose will power the hundreds of

F-35 Lightning II stealth fighters operated by the U.S. military and its allies across the globe. Given that the F-35 is the

most expensive defense program in history, the stakes are high.

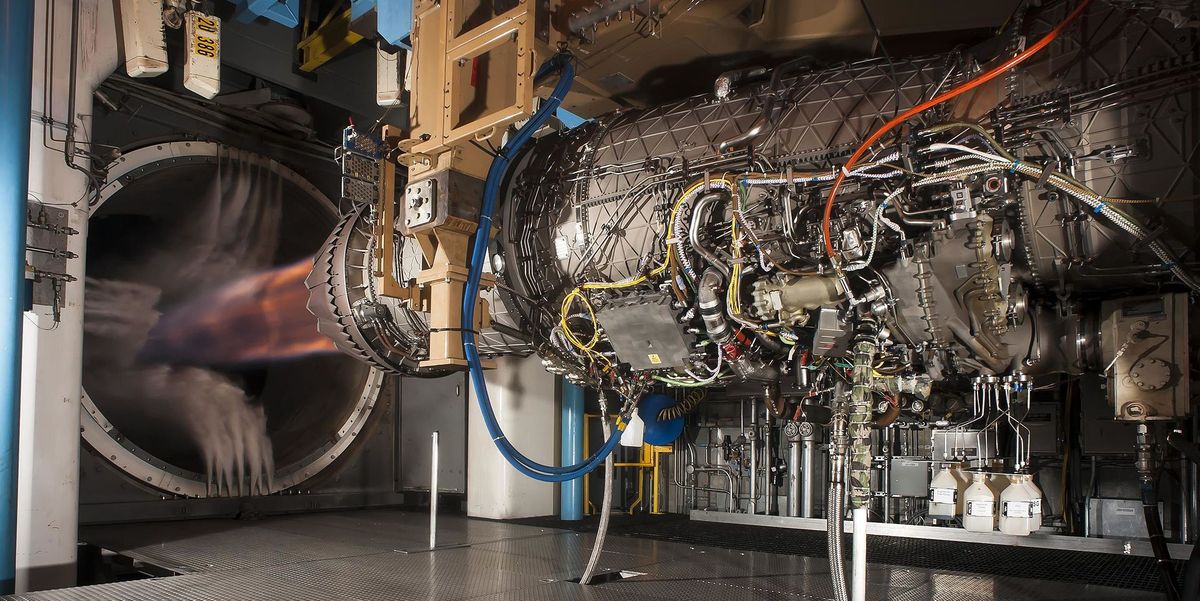

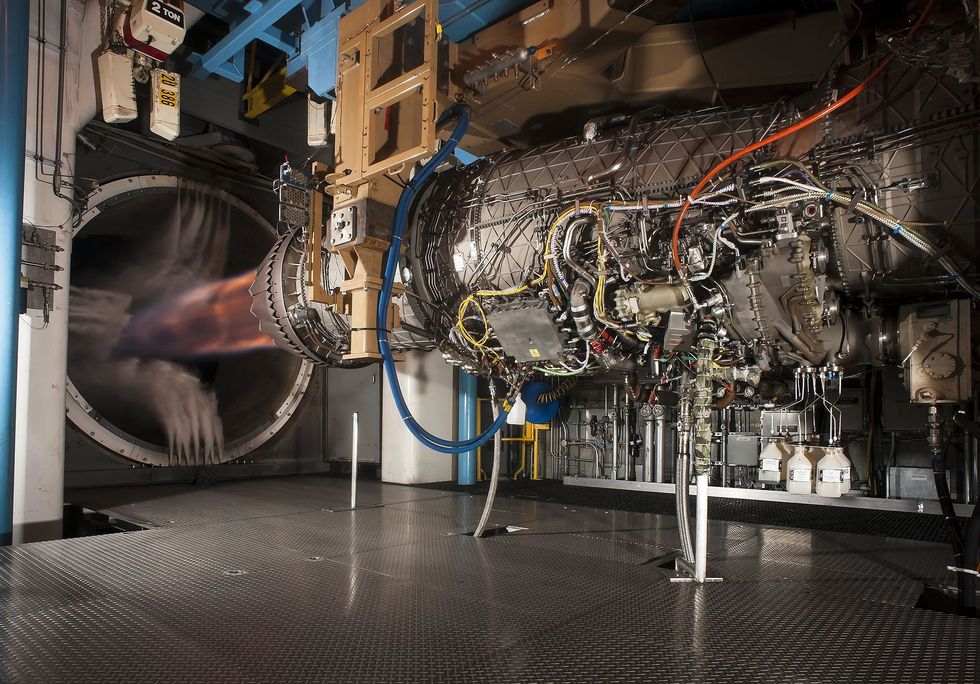

Presently, the F-35 uses Pratt & Whitney’s F135 turbofan engine, or the F-135-600 version for the

Marine’s F-35B jump jet model. Developed from the F119 engine used by the F-22 Raptor stealth fighter, the F135 can generate 28,000 pounds of thrust, or 43,000 with afterburner; and withstand 3600 degrees Fahrenheit of heat. The almost two-ton engine is assembled in a factory in Middletown, Connecticut, with some subcomponent built in Canada and Poland.

An F135-PW-100 powerplant.

Wikimedia Commons

The hugely expensive and much delayed

Block 4 upgrade to the F-35 currently in progress, however, requires an engine that can generate more electricity for systems integrated into the F-35. Better thermal management is also required, as F-35s already

struggle sometimes with the current load, and the addition of Block 4 systems will increase that burden. Thus, a failure to improve the engine would reportedly

raise operating costs and reduce engine life.

More From Popular Mechanics

The History of the B-2 Spirit

Advertisement - Continue Reading Below

The F135 has had a bumpy ride recently. The crash of a hovering F-35B jump jet on December 14, 2022 led to a freeze on F135 deliveries 13 days later. Subsequently, Pratt & Whitney identified engine vibrations (“harmonic resonance”) causing the failure of a high-pressure fuel tube as the culprit. A fix dampening engine vibrations is being implemented going forward. Pratt & Whitney claims deliveries may

resume in March, though it’s unclear how fixes could be retrofitted to already delivered engines.

This content is imported from youTube. You may be able to find the same content in another format, or you may be able to find more information, at their web site.

Earlier, there were also reports that sustained use of the afterburners

could damage the F-35’s tail, leading the Marine Corps and Navy to quietly self-impose a 40- to 80-second time limit on after burner usage.

The debate now concerns whether the F135 engine should receive an evolutionary update, or be entirely replaced with a new adaptive cycle-engine that can reconfigure itself midflight to optimize fuel efficiency or thrust as needed.

The Air Force has devoted $4.4 billion to developing adaptive-cycle engines since kicking off a program called ADVENT in 2007. This morphed in 2016 into the Adaptive Engine Transition Program (AEPT), in which both GE and Pratt & Whitney were contracted to separately develop prototype engines, called the XA-100 and XA-101, respectively.

AETP technology was foremost intended to prep for the U.S.’s forthcoming

next-generation air dominance (NGAD) fighter—but it would also be explored as a

possible upgrade for the F-35, too. AETP’s goal was a new engine that hoped to improve fuel efficiency by 25 percent, increase thrust by 10 percent, and boost thermal management compared to the F135.

Advertisement - Continue Reading Below

Though Pratt & Whitney developed an adaptive-cycle engine called the XA101, the company’s F135 program head Jennifer Latka

argued the AETP engines were “not the right fit for the F-35” and that it made more sense to reserve adaptive cycle technology for NGAD. Instead, the company would rather develop an evolutionary Engine Core Upgrade (ECU), increasing the F135’s thrust by 10 percent and fuel efficiency by 5 percent (resulting in 7 percent increased range), while

supposedly reducing costs of a shop visit by 36 percent.

But rival General Electric wants the Air Force to toss the F135 and re-engine with its own XA-100 adaptive cycle engine. Already, two flight weight XA100 prototypes completed testing in 2022. This XA100 supposedly would increase fuel efficiency by 25 percent (resulting in a 30- to 35-percent increase in range), allow a 10- to 20-percent increase to thrust, and absorb twice as much heat.

This content is imported from youTube. You may be able to find the same content in another format, or you may be able to find more information, at their web site.

In theory, the XA-100 offers far more considerable performance improvements. However, rival Pratt & Whitney claims developing its ECU would cost $2.4 billion compared to $6.7 billion for the rival XA-100, and that its evolutionary upgrade would result in

$40 billion lower life-cycle costs.

GE argues the successful F-16 and F-15 fighters also transitioned to different engines with satisfactory results—notably from Pratt & Whitney’s F100 to General Electric’s F110. GE’s advanced propulsion manager David Tweedie

told Aviation Week he believes the new engine could be “seamlessly” integrated into F-35s by 2028, though the F-35’s Joint Project Office may envision a later 2031 date.

Adaptive Cycle Engine: From Concept to Reality

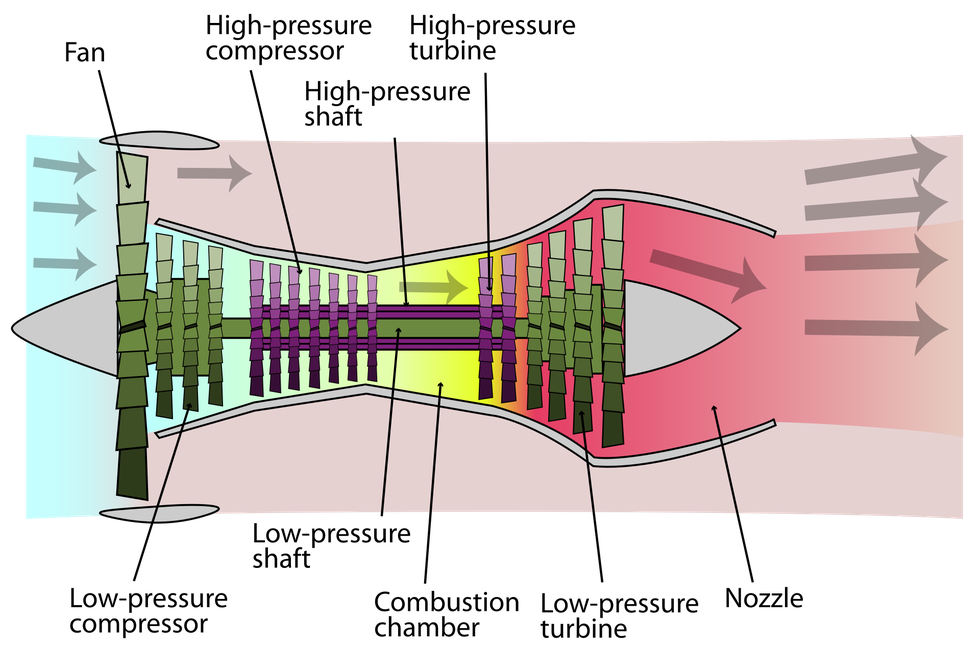

Most modern jets use turbofan engines, which squeeze air through a compressor and combustion chamber, while allowing additional air to bypass the engine core. The higher the ratio of air bypassing the compressor, the more fuel-efficient the aircraft, particularly when flying below the speed of sound. But if you want to maximize thrust to accelerate rapidly and sustain high speeds—you know, like a jet fighter in combat—you want a lower bypass ratio, even though it comes at a cost in fuel efficiency.

Wikimedia Commons

Advertisement - Continue Reading Below

The premise with the adaptive cycle engine is that you can have your cake and eat it, too: the engine redirects a third stream of air midflight based on the desired performance regime.

The XA-100 has an adaptive fan that can direct air to an additional third bypass stream to max out fuel efficiency and electricity generation, but can redirect air directly into the compressor instead when necessary to juice up kinematic performance. The third stream also greatly improves cooling, which is vital as aircraft like the F-35 harness increasingly more powerful sensors and avionics, and eventually

directed energy weapons like lasers. The XA-100 is also built with new ceramic matrix composites to further improve heat resistance.

The XA-100 could help mitigate one of the F-35’s biggest weaknesses: its limited range (without aerial refueling), which means that in a theater like the Pacific, F-35s must be

based within easy striking range of land-based ballistic missiles. Improved thrust could also reduce the type’s

kinematic deficits compared to fourth-generation non-stealth fighters, improving capability in within-visual range combat.

But there are considerable costs and technical risks involved in integrating an entirely new engine, however good. Already, the F-35 has served as an object lesson of how integrating multiple new technologies can

results in delays and skyrocketing development costs.

Another issue is that

two new F135 replacements might actually have to be developed—one for Air Force and Navy F-35As and Cs, and another for the F-35B jump jet unique F135-600 engine.

The Tradeoffs

Overall, there’s little doubt adaptive cycle engines have major benefits and will likely feature prominently in the forthcoming

sixth generation of combat aircraft. But the question remains whether it makes sense to retrofit an entirely new engine to the fifth-generation F-35, which has only just begun to overcome epic growing pains making it into service and remains

very expensive to operate per flight hour.

Advertisement - Continue Reading Below

A defense analyst with years of experience supporting various defense aerospace programs such as the F-35,

B-21, and

next-generation programs, who chose to remain anonymous, told

Pop Mech:

“Right now, there’s a growing sense of urgency in the USAF to get the ball rolling on F-35 Block IV upgrades. If we were to go to war right now, I think a match-up between current F-35s and

J-20s [China’s current operational stealth fighter] would be uncomfortably close. I think we’ll see some Block IV upgrades be dropped or come out staggered and be integrated into earlier lots before the first ‘all Block IV’ production models come out in the latter part of this decade (hopefully).”

In his view, getting the much delayed Block IV model “out of the door” should be a priority:

“I’m not ‘read-in’ to all of Block IV (it’s very closely guarded) but I’ve heard we’re doing well in adaptive cycle engine development. My concern for the XA-100 is the same as it is for so many other upgrades to the F-35—integration. Personally, I would just upgrade the F135s if it saves us years of development and integration. And if it does, I think that’s the way the Department of Defense will go. Especially since General Charles Brown, General David Berger, and Admiral Mike Gilday [chiefs of the Air Force, Marine Corps, and Navy respectively] aren’t particularly wed to the F-35 like some of their predecessors have been…”

In his estimation, adaptive cycle engines might not be most cost-efficient solution for the F-35’s problems:

“There are other ways we can compensate for the range/efficiency we need that an adaptive cycle engine can give us. Plus we can focus our adaptive cycle engine efforts on NGAD and NGAD-N [the Navy’s next-generation fighter program].”

Presently, the Pentagon is hedging its bets, awarding Pratt & Whitney

a $115 million contract in December 2022 to begin preliminary work on its more conservative ECU upgrade, a project that already involves 250 engineers; while giving General Electric $203 million to sustain 400 staff working on the XA100 in Ohio until a decision is made.

Further hints as to which path lawmakers in Washington will favor are expected when the Biden administration releases its 2024 defense budget request in March. Meanwhile, adaptive cycle engine development specifically aimed at sixth-generation combat aircraft is now being spun-off into a $5 billion program called Next Generation Adaptive Propulsion (NGAP).

Contributor

Sébastien Roblin has written on the technical, historical, and political aspects of international security and conflict for publications including 19FortyFive, The National Interest, MSNBC, Forbes.com, Inside Unmanned Systems and War is Boring. He holds a Master’s degree from Georgetown University and served with the Peace Corps in China. You can follow his articles on

Twitter.