http://forums.bharat-rakshak.com/viewtopic.php?f=3&t=5719&start=80

An overview of the Kaveri situation was provided by the GTRE director, T. Mohan Rao, who was accompanied by his senior scientists. The hall was packed, and the language and tone of his speech was sadly self-depracating and pleading. Almost as if DRDO has also started losing faith - he had to explain whats going on and why its happening. Sad to see, but there are clear silver linings in the story.

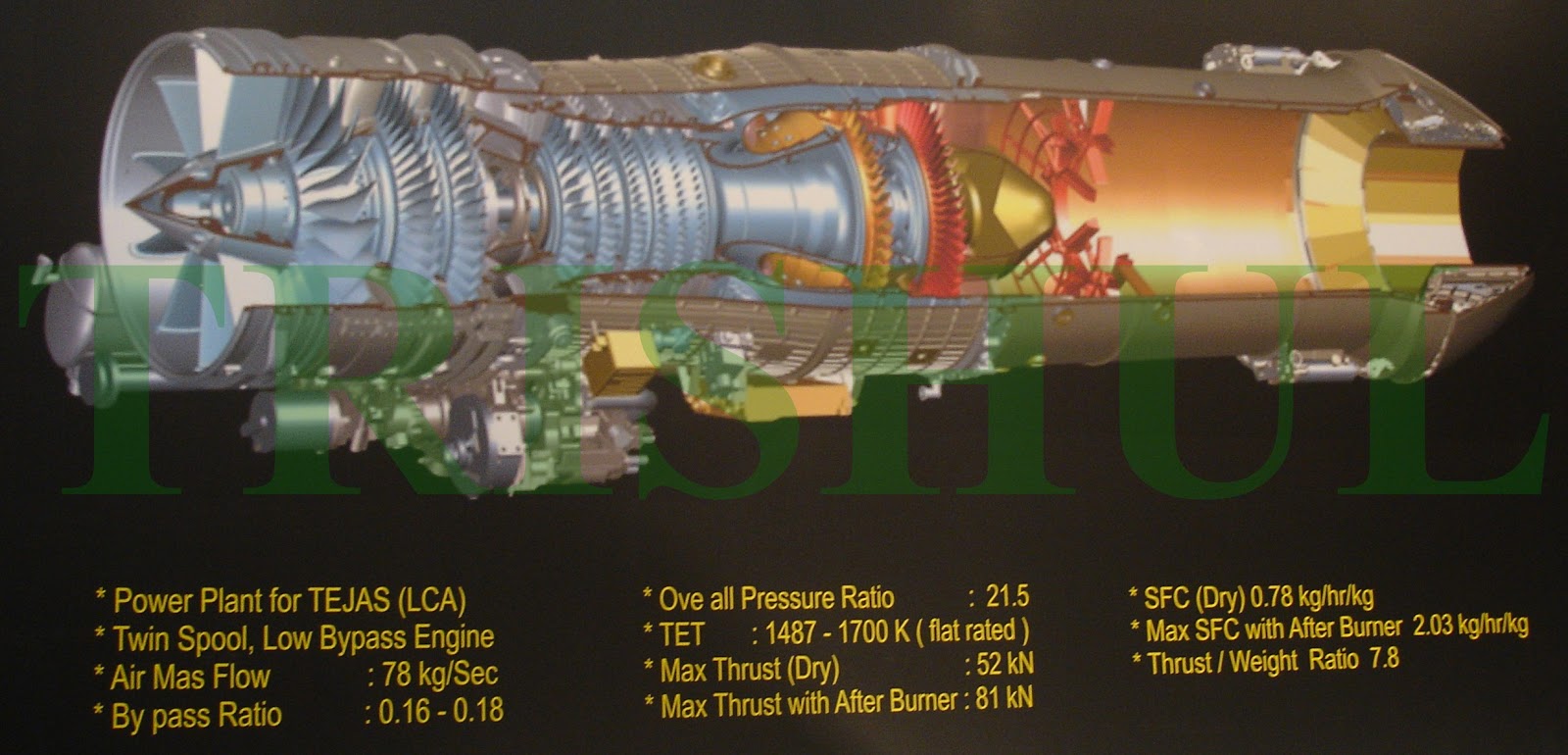

1. He pointed out that the change in IAF requirements and the increase in all up wt by 2 tons killed the Kaveri as they knew it, simply because it could not in any way be able to achieve the new requirements... he was quite angry that they had been blamed for what was obviously not their fault, ie, a low-performing Kaveri for the updated reqs. Bypass Ratio is 0.16 to 0.18... he pointed out that if it had to meet the new stds, the bypass would have to be at least 0.35 to 0.45.

2. 4 Cores and 8 Kaveris built, 1800 hrs testing done.

Thrsut demonstrated: 4774 kgf dry (design value reached). 7000 kgf reheat (2.5-3% shortfall)

3. Pressure ratio - 21.5 overall.

Fan - 3 stage, 3.4 pressure ratio, Surge margin>20.

Compressor 6.4 pressure,Surge>23.

Combustor - efficiency >99%, high intensity annular combustor. Pattern factor of 0.35 and 0.14

Note: These are ACHIEVED values.

4. The present Kaveri will not power combat LCAs, although it will be fitted to an LCA within 9 months. The new program, which is the Kaveri with Snecma Eco core of 90kN will be used. The preslim design studies and configuration have beeen completed.

5.Birdhit requirements of 85% thrust after hit at 0.4-0.5 Mach have been shown and achieved.

6. He pointed out the major factor in delays being them not being given enough infrastructure and testing facilities - Govt has not given funds, babus have sat on them. Instead, they have had to go to CIAM in Russia and Anecom in Germany for tests.

He mentioned that this was the biggest problem - one of the issues they have was in engine strain and the blade throws - they tried to isolate all the causes for 3 yrs, but only when they took it to CIAM for the Non Intrusive Strain Measurement (NSMS) tests did they realize that there were excess vibrations of the 3rd order of engine frequency being developed.... imagine if the facility was there in india.

Then, the compressor tests also, it was only at the Anecom that they could see that the 1st 2 stages were surged by 20%, while the rest were "as dead as government servants" (his quote - shows how low on confidence they are i guess). He pointed out that that would have saved a lot of time and money if that facility was in india. They have since fixed the issue.

Then, the afterburner tests, (the much highlighted high altitude failure) at CIAM - the reqt is for 50% thrust boost over dry thrust at 88% efficiency. The K5 prototype failed in 2003, after working perfectly in the GTRE. They realized that they could not achieve lightup at high altitudes (Dry thrust worked ok).

They took anothe new engine block and the afterburner worked perfectly and has been certified to 15 km.

7. The good news..... they will conduct complete engine trials in CIAM in March. If these trials are successful (and they are highly confident), the Kaveri will be integrated on the LCA within 9 months.

The KADECU FADEC system with manual backup has also been fully certified.

8. The bad news again - The present requirements would need the core to pump out 15-20% more power, which is impossible... hence the eco. Not that there is anything wrong with the core.

He mentioned that otherwise, the Kaveri has met the original requirements, or will meet within the next month, and is good for all other uses except a "combat LCA" - ie, CAT, LIFT, LCA Trainer, etc.

9. When asked where we lack, he mentioned 4 key areas

a. BLISK - integrated single Blade and Disk

b. Single Crystal blades - he categorically said - We do not have that tech at all.

c. Thermal Barrier Coatings - TBC - very critical for high temp engine operation. A talk on this by an American Indian prof attracted a house full audience. He mentioned that this is highly critical and export controlled, so they dont have it.

The last two points were mentioned by Dir, DMRL as one of their areas of research, but I was not able to quiz him on it. PLEASE QUIZ ANY DMRL GUYS U MEET ON THIS.

Mohan Rao appealed that people should realize that this tech takes time, and money, and more importantly, willpower and support.... its not being given by foriegn nations, so if we have to develop, it needs support. This stance found strong support from Saraswat, Sundaram and Selvamurthy in the closing ceremony.

They are not looking at TVC just yet, and it is in the hands of other labs at the moment.

However, the ADE presentation on UCAVs showed a future Indian UCAV (2015) with no tail (MCA design), a non-conventional wingform, and a 3 axis TVC.

10. OK, some nos....

Fan - Successful tests at CIAM

Compressor: (nos in brackets are design values)

6 stage axial flow, 3 stage variable vanes with IGVs.

Corr. tip speed ~370 m/s

Inlet diam: 590 mm

Mass flow: 24.13 kg/s (24.3)

Pressure: 6.42 (6.38)

Efficiency: 85.4% (85%)

Surge %: 21.6 (20% designed)

Combustor:

Has undergone aero testing at CIAM

K8 V4 combustor is close to design.

Turbine:

Pressure = 3.6

Mass flow function= 1.1

Isentropic eff = 85%

Max. TET = 1700K

Is a success, has met design.

11. Future uses:

Navy - KMGT - 1 MW for small ships being developed, 5-6 MW KMGT is a sucess and runs on Diesel, instead of the usual kerosene aviation fuel.

The railways also wants a 7-8MW CNG run engine, which will be a challenge in terms of fuel supply, rather than teh combustion itself, which shouldn't be a problem.

This too is as late as 2011, I don't know whether the russians transferred the SCB tech after 2011 and HAL has already placed a AL-31 FP with HAL made SCBs on the first Sukhoi it produced.

To conclude so, What we need is proof.

After that this post details the local effort,

As per the info I got at Aero India we have developed single crystal blades aside from what we got from Russia with Su 30.

Here is how it is done. Ceramic cores are first made and blades are grown around the cores. The cores are later dissolved away leaving an internal structure that allows cooling.

Image shows ceramic cores

The squiggly bits are electrodes that are removed from the finished blade

Blurred close up shows hollow internal structure of blade created by preformed ceramic core that was removed

To conclude whether the above local effort combined with Russian TOT on SCB has bestowed SCB tech with a TWR of 8 (wet thrust) on HAL needs proof not some one's opinion.