Backgrounder from

French Safran asked India to invest close to 6000 Cr and committed to investing 3000cr of its investment as part of Rafale offset obligations to revive India’s now stalled Kaveri engine program French offer was considered too pricey by DRDO.

DRDO already has invested over 3000cr in the Kaveri engine program but an additional investment for 6000 cr only to get core section of M-88-3 engines which included custom modification of the new Kaveri engine with Indian developed technology, and later certification of the modified engine along with ToT cud hv meant that

SAFRAN enjoyed Royalty for its tech for decades to come acc to DRDO at least for Tejas Mk1A and MWF program they are sticking with USA's GE F404-IN20 (84 kN) and 414-GE-INS6 (98 kN) turbofan engines and Even for Naval Mk2 program, GE’s F414 turbofan engines are preferred but the

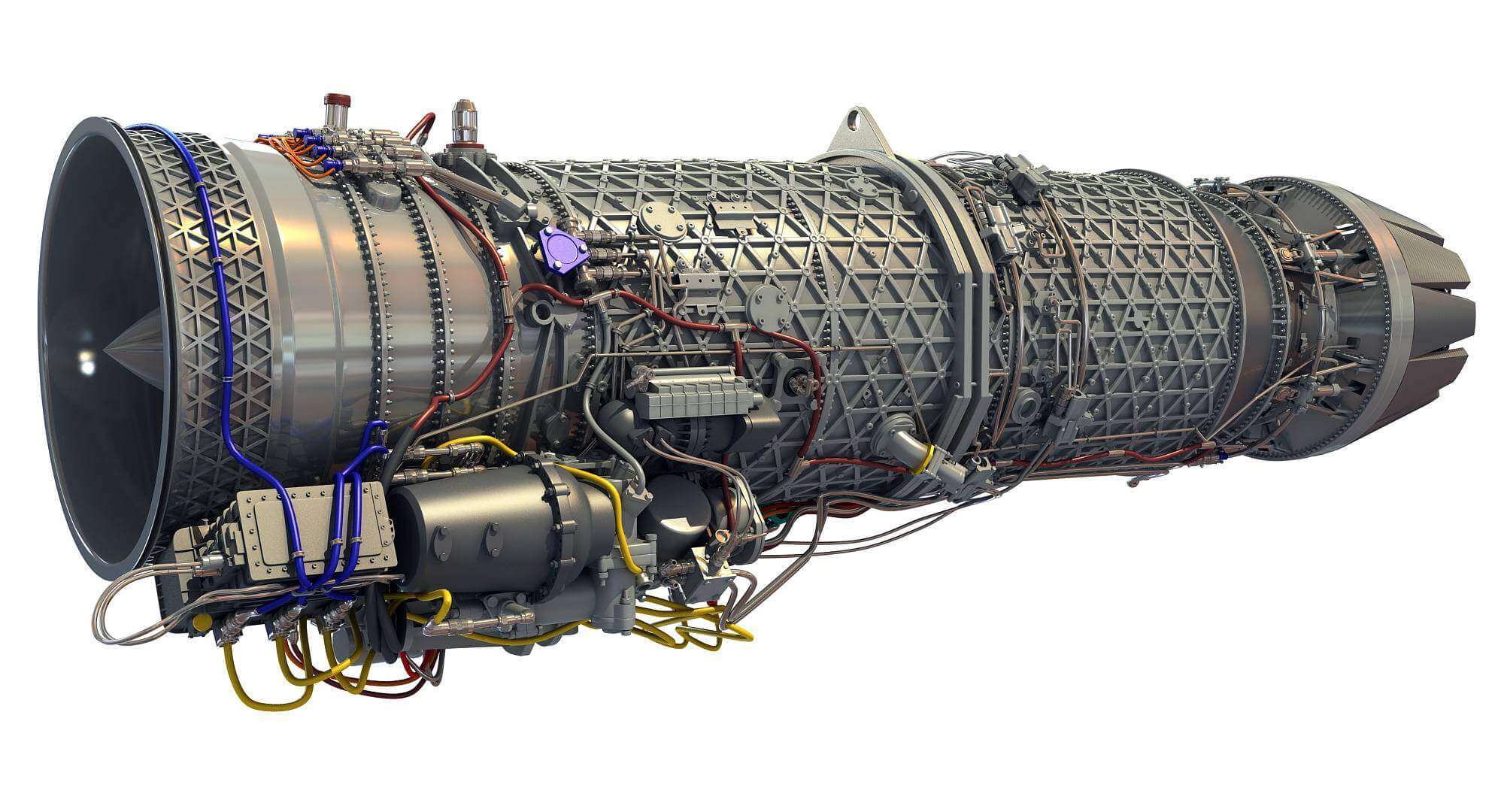

problem with GE hs being is that these engines are brought off the shelf n hs no option of even local license assembly let alone any ToT of Key core tech Prototypes of 5th Gen AMCA Stealth fighter jets will use GE’s F414 in the initial stage bt d aircraft requires more powerful engine which cn generate 110kN of Thrust class over what current GE engines cn generate 98kN for which GE hs offered India its F414 Enhanced Engine which it says will be ready by 2022. F414 Enhanced Engine which has been under development for the US Navy for its F/A-18 E/F and EA 18G aircraft fleet will be able to generate around 116kN Thrust class which is 18% improvement over Standard F414 engines. GE believes F414 Enhanced Engines which will go into production by 2022 n already hs orders worth $630 mn frm US Navy to replace older engines in its aircraft will make it a perfect fit for d AMCA pro since the developmental cost of the program already is funded by US Navy.

British Defence Secretary in his visit to India in 2017 had offered India to jointly develop a new engine based on EuroJet turbofan engine which powers Eurofighter Typhoon. The UK already has invited India to co-develop a 6th-gen fighter called the Tempest but o decision has been taken yet but India is yet to take a call on co-development offer on both engine and new 6th generation fighter aircraft Wth the United Kingdom. Military think tanks in India have called for the revival of Kaveri engine program so that India is not left behind in the development of mil-grade turbo class engines for its fighter n transport aircraft programs and hv called upon Modi govt to inject program wth more funds n new engineers n scientist along wth the participation of private sector to kick start the program again. DRDO officials believe the key decision on the direction of the program will be taking place next few months, will DRDO get-go head to have talks with RR or new core team will be formed to develop new higher thrust engines with fresh funding what will chart the future course of military jet engines development in India.

My take- US offers cutting edge tech only when we are close to realizing it ourselves (in this case with help from RR). Can the people handling these negotiations arm-twist GE to part with IPR of the 116kN thrust 414EPE?

Advantages - dev cost already footed by USN and ready by 2022. Enhancements are incremental and can be retrofitted into all F414s as per

https://idrw.org/ex-drdo-chief-vk-saraswat-to-suggest-a-path-for-advanced-110kn-thrust-class-engine/

At stake is a chokehold on one of the world's largest jet engine markets with a requirement of 1400+ engines over 3-4 decades for LCA Mk2 and AMCA.