India's progress in fusion energy.

- Thread starter fire starter

- Start date

More options

Who Replied?- Joined

- Jan 14, 2020

- Messages

- 9,609

- Likes

- 84,139

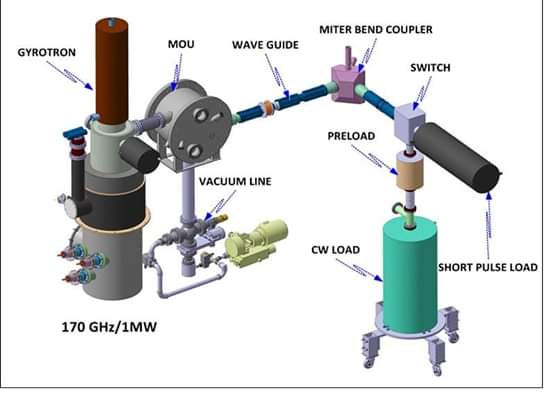

Magnet for Gyrotron developed by India for its fusion reactors.

Gyrotrons are used in nuclear fusion research experiments to heat plasmas.

For the first time in the country, Magnet Division has realized the complex high homogeneity superconducting cavity magnet system together with a low loss cryostat and necessary quench protection measures. These magnets have successfully operated for long durations (> 4 hours) of gyrotron testing. On the protection of high current carrying high field magnets, a new technology of `hybrid breaker’ using parallel IGBTs have been successfully demonstrated. These technologies can now be extended towards the protection of fusion relevant magnets system in Tokamak.

Gyrotrons are used in nuclear fusion research experiments to heat plasmas.

For the first time in the country, Magnet Division has realized the complex high homogeneity superconducting cavity magnet system together with a low loss cryostat and necessary quench protection measures. These magnets have successfully operated for long durations (> 4 hours) of gyrotron testing. On the protection of high current carrying high field magnets, a new technology of `hybrid breaker’ using parallel IGBTs have been successfully demonstrated. These technologies can now be extended towards the protection of fusion relevant magnets system in Tokamak.

piKacHHu

New Member

- Joined

- Sep 5, 2015

- Messages

- 323

- Likes

- 994

This reply may be slightly off topic given the energy through Thorium is extracted through Fission process (i.e. Splitting of Atoms/Nucleus).How many Thorium Reactors does India have ??

How are thorium reactors different from Fusion reactors ??

As of now there is NO thorium based reactor operating in India. There have been demonstration of Thorium cycle through some test reactors like Fast Breeder Test Reactor (FBTR) but there is no fully operational reactor entirely based on Thorium right now.

Thorium reactors or rather Thorium based reactors are quiet different than the conventional Uranium based Nuclear Reactors. Firstly, the Thorium (Th-232) is not a Fissile isotope unlike Uranium-235/Pu-239/U-233 which undergoes nuclear chain reaction with low energy neutrons very rapidly. Therefore, there is an additional step in Thorium reactors to convert Fertile Thorium-232 to Uranium-233 isotope which is one of the Fissile isotope of Uranium. This conversion is called Breeding of Fissile Material. Fast Breeder Reactors (Fast stands for Fast Neutron with high kinetic energy) are used to convert the blanket of Thorium around it to Fissile Uranium isotope.

In second phase, the resulting Uranium-233 is utilized in thermal reactors (i.e. based on neutrons of lower energy) to generate power as well as breeding the Thorium to U-233, if it is present around. This concept is called Thermal breeding as U-233 for lower energy neutrons gives good performance in converting Fertile into Fissile material and further Fission of Fissile material is utilized for electric power generation or Nuclear Propulsion.

Fusion reactors , on the other hand, works on the principle of fusion or joining of nuclei resulting into a heavier nuclei and energy (Difference of Mass in the reaction gets converted into energy, Hence, E = MC^square). So, in this case, two Hydrogen atoms get combine to produce Helium plus the Energy. Challenge for Fusion reactors is that Fusion takes place at very high temperature plus to increase the probability of interaction among the atoms, you need to confine the Lightest atom on the earth i.e. Hydrogen in a very small confinement volume. That is why exploitation of Fusion reaction of energy generation is still in exploratory mode.

LETHALFORCE

New Member

- Joined

- Feb 16, 2009

- Messages

- 29,968

- Likes

- 48,929

HariPrasad-1

New Member

- Joined

- Jan 7, 2016

- Messages

- 9,645

- Likes

- 21,138

We need to allocate more and more fund on research. With BJP coming to power, nothing appears to have changed on allocation front or in policy matter in research.

Bhadra

New Member

- Joined

- Jul 11, 2011

- Messages

- 11,991

- Likes

- 23,756

The other day I sincerely asked in the forum about the Indian thorium reactor. Some great Scientist @fire starter cooly replied those were fission reactors.

The great scientists of the forum throwing their gyaan in all kind of pics never thought it right to correct him that thorium reactors were actually "cool fusion" reactors... or at best "fussion- Fission" ones... with emphasis on Fusion....

Let us have another one....

The great scientists of the forum throwing their gyaan in all kind of pics never thought it right to correct him that thorium reactors were actually "cool fusion" reactors... or at best "fussion- Fission" ones... with emphasis on Fusion....

Let us have another one....

piKacHHu

New Member

- Joined

- Sep 5, 2015

- Messages

- 323

- Likes

- 994

I believe I explained enough about Thorium reactor and difference between it and the fusion reactors in simplest terms.The other day I sincerely asked in the forum about the Indian thorium reactor. Some great Scientist @fire starter cooly replied those were fission reactors.

The great scientists of the forum throwing their gyaan in all kind of pics never thought it right to correct him that thorium reactors were actually "cool fusion" reactors... or at best "fussion- Fission" ones... with emphasis on Fusion....

Let us have another one....

This reply may be slightly off topic given the energy through Thorium is extracted through Fission process (i.e. Splitting of Atoms/Nucleus).

As of now there is NO thorium based reactor operating in India. There have been demonstration of Thorium cycle through some test reactors like Fast Breeder Test Reactor (FBTR) but there is no fully operational reactor entirely based on Thorium right now.

Thorium reactors or rather Thorium based reactors are quiet different than the conventional Uranium based Nuclear Reactors. Firstly, the Thorium (Th-232) is not a Fissile isotope unlike Uranium-235/Pu-239/U-233 which undergoes nuclear chain reaction with low energy neutrons very rapidly. Therefore, there is an additional step in Thorium reactors to convert Fertile Thorium-232 to Uranium-233 isotope which is one of the Fissile isotope of Uranium. This conversion is called Breeding of Fissile Material. Fast Breeder Reactors (Fast stands for Fast Neutron with high kinetic energy) are used to convert the blanket of Thorium around it to Fissile Uranium isotope.

In second phase, the resulting Uranium-233 is utilized in thermal reactors (i.e. based on neutrons of lower energy) to generate power as well as breeding the Thorium to U-233, if it is present around. This concept is called Thermal breeding as U-233 for lower energy neutrons gives good performance in converting Fertile into Fissile material and further Fission of Fissile material is utilized for electric power generation or Nuclear Propulsion.

Fusion reactors , on the other hand, works on the principle of fusion or joining of nuclei resulting into a heavier nuclei and energy (Difference of Mass in the reaction gets converted into energy, Hence, E = MC^square). So, in this case, two Hydrogen atoms get combine to produce Helium plus the Energy. Challenge for Fusion reactors is that Fusion takes place at very high temperature plus to increase the probability of interaction among the atoms, you need to confine the Lightest atom on the earth i.e. Hydrogen in a very small confinement volume. That is why exploitation of Fusion reaction of energy generation is still in exploratory mode.

" thorium reactors were actually "cool fusion" reactors... or at best "fussion- Fission" ones... with emphasis on Fusion."

I would like to be enlighten about this statement. Thorium being used in "cool fusion" & "Fusion-Fission" process is quite unheard of. And for the record, Conversion of Thorium into Uranium-233 via (n,gamma) reaction is called breeding of fissile material.

For pictures, if someone is so eager to share, then should also put some effort to explain what's in the pic. Most of them are related to Indian contribution to fusion project as part of collaboration with IPR & ITER.

Bhadra

New Member

- Joined

- Jul 11, 2011

- Messages

- 11,991

- Likes

- 23,756

Thank you for such a nice explanation.This reply may be slightly off topic given the energy through Thorium is extracted through Fission process (i.e. Splitting of Atoms/Nucleus).

As of now there is NO thorium based reactor operating in India. There have been demonstration of Thorium cycle through some test reactors like Fast Breeder Test Reactor (FBTR) but there is no fully operational reactor entirely based on Thorium right now.

Thorium reactors or rather Thorium based reactors are quiet different than the conventional Uranium based Nuclear Reactors. Firstly, the Thorium (Th-232) is not a Fissile isotope unlike Uranium-235/Pu-239/U-233 which undergoes nuclear chain reaction with low energy neutrons very rapidly. Therefore, there is an additional step in Thorium reactors to convert Fertile Thorium-232 to Uranium-233 isotope which is one of the Fissile isotope of Uranium. This conversion is called Breeding of Fissile Material. Fast Breeder Reactors (Fast stands for Fast Neutron with high kinetic energy) are used to convert the blanket of Thorium around it to Fissile Uranium isotope.

In second phase, the resulting Uranium-233 is utilized in thermal reactors (i.e. based on neutrons of lower energy) to generate power as well as breeding the Thorium to U-233, if it is present around. This concept is called Thermal breeding as U-233 for lower energy neutrons gives good performance in converting Fertile into Fissile material and further Fission of Fissile material is utilized for electric power generation or Nuclear Propulsion.

Fusion reactors , on the other hand, works on the principle of fusion or joining of nuclei resulting into a heavier nuclei and energy (Difference of Mass in the reaction gets converted into energy, Hence, E = MC^square). So, in this case, two Hydrogen atoms get combine to produce Helium plus the Energy. Challenge for Fusion reactors is that Fusion takes place at very high temperature plus to increase the probability of interaction among the atoms, you need to confine the Lightest atom on the earth i.e. Hydrogen in a very small confinement volume. That is why exploitation of Fusion reaction of energy generation is still in exploratory mode.

- Joined

- Jan 14, 2020

- Messages

- 9,609

- Likes

- 84,139

Upgradation of Aditya Tokamak 2015.

One of the important modification in the upgradation of Aditya tokamak is the replacement of the rectangular cross section vacuum vessel by circular cross section with vessel baking facility. as shown in the third Picture. The cross section of vessel has been designed as circular to accommodate eight vertical field coils including main divertor coils (4 Nos.), Auxiliary Divertor Coils (2 Nos.), Fast feedback coils (2 Nos.) in the available

space between circular vessel and toroidal field coils. The new toroidal vacuum vessel has been designed with two semi-tori having electrical isolation at two junctions. The major radius (0.75 m) and minor radius (0.25 m) has been kept same as of old torus.

In order to accommodate as many numbers of diagnostics as possible, the vessel has been designed to have 112

port openings (including four Tangential Ports) compared to 48 ports of the old vessel. The shell formation and fabrication for torus, leak proof, UHV condition, precise dimensions and lots of weld and demountable joints in the new vessel had made the fabrication job very challenging. It has been precisely fabricated as per design.

One of the important modification in the upgradation of Aditya tokamak is the replacement of the rectangular cross section vacuum vessel by circular cross section with vessel baking facility. as shown in the third Picture. The cross section of vessel has been designed as circular to accommodate eight vertical field coils including main divertor coils (4 Nos.), Auxiliary Divertor Coils (2 Nos.), Fast feedback coils (2 Nos.) in the available

space between circular vessel and toroidal field coils. The new toroidal vacuum vessel has been designed with two semi-tori having electrical isolation at two junctions. The major radius (0.75 m) and minor radius (0.25 m) has been kept same as of old torus.

In order to accommodate as many numbers of diagnostics as possible, the vessel has been designed to have 112

port openings (including four Tangential Ports) compared to 48 ports of the old vessel. The shell formation and fabrication for torus, leak proof, UHV condition, precise dimensions and lots of weld and demountable joints in the new vessel had made the fabrication job very challenging. It has been precisely fabricated as per design.

- Joined

- Jan 14, 2020

- Messages

- 9,609

- Likes

- 84,139

Indian Made Cryostat Installation at ITER fusion reactor.

In a 5,000-square-metre workshop on site, the Indian Domestic Agency is assembling the cryostat—a huge vacuum containment vessel that is also the single largest component of the ITER machine.

Completely surrounding the vacuum vessel and superconducting magnets, the 29 x 29 metre cryostat has two important roles to play—providing a vacuum environment to critical "cold" components (the magnets operating at 4.5 K and thermal shield operating at 80 K), and contributing structural reinforcement by supporting the mass of the machine and transferring horizontal and rotational forces to the radial walls.

The cryostat is a fully welded single wall stainless steel structure with a flat bottom, a rounded lid and wall thicknesses that range from 25 to 200 millimetres. A number of large openings provide access to vacuum vessel ports at three levels; others allow access for coolant pipework, cryo and current feedlines, and remote handling. Advanced welding techniques such as automated, all-position narrow groove gas tungsten arc welding have been specially developed for the fabrication of this challenging component.

Manufacturing is taking place in three stages: the fabrication of 54 segments in India; their subsequent assembly at ITER into four large sections (base, lower cylinder, upper cylinder, top lid); and the final assembly and welding of the large sections in the Tokamak Pit.

The cryostat is a vacuum-tight container that will completely surround the machine and provide an ultra-cool vacuum environment for the vacuum vessel and superconducting magnets. Welding operations are underway now on the cryostat base and lower cylinder, two of the four large sections that will be assembled and welded on site.

Cryostat segments fabricated in India are shipped according to need dates to the ITER site and stored in the Cryostat Workshop.

Beginning with the cryostat base—the first cryostat section needed in the Tokamak assembly sequence—and ending with the cryostat lid, the sections are assembled and welded on large assembly frames. These frames act both as support platforms during the welding activities and as support fixtures that interface with the transport vehicles when the time comes to move the completed components out of the workshop.

Using optical metrology techniques and strict dimensional control, operators carefully align the segments to be welded on the assembly frames. A small team of highly specialized technicians—working singly or in teams (one above, one below)—fill the gaps between each segment with weld material. Given the importance of high vacuum in the cryostat, each weld is verified through a variety of leak detection techniques.

In helium leak detection, one-metre sections of the weld to be verified are "enclosed" within leak-tight boxes positioned on opposite surfaces. Helium injected on one side of the weld can be detected—if it has filtered through a crack—by a mass spectrometer on the other side, thereby signalling a leak that must be repaired by grinding out the faulty weld and replacing it.

Three other quality assurance techniques will be used: radiographic and ultrasonic testing to detect the presence of flaws that could challenge the structural integrity of the welds, and liquid penetrant testing (LPT) for surface checks.

In total, the Indian Domestic Agency estimates that one kilometre of full penetration weld joints will have to be carried out to exacting standards for the sub-assemblies in the site workshop, followed by several hundred metres of weld joints to assemble the cryostat sections in the Tokamak Pit.

It took approximately three years (2016 to 2019) to finalize the on-site assembly and welding operations for the cryostat base—a 1,250-tonne component formed from a tier 1 "disk" and a tier 2 vertical ring and pedestal.

On an adjacent assembly platform, the less-complex lower cylinder (490 tonnes) was assembled in two years (2017 to 2019) and removed to storage on the platform to make room for the assembly of the upper cylinder, which was completed in March 2020. The steel segments required for top lid assembly are expected on site in mid-2020.

In April 2020, the 1,250-tonne cryostat base was removed to the Assembly Hall, where it will be prepared for transport by overhead crane into the bottom of the Tokamak assembly pit. This will be the official start of ITER machine assembly.

Cryostat Assembly Facts:

Number of segments fabricated in India: 54.

Sections assembled on site: cryostat base, lower cylinder, upper cylinder, top lid.

Length of weld joints for in-workshop assembly (four sections): ~ 1,015 m.

Length of weld joints for in-pit assembly: ~ 390 m.

Diameter of sections: 30 metres (approximate).

Weight of each section: base: 1,250 tonnes; lower cylinder: 490 tonnes; upper cylinder: 430 tonnes; lid: 665 tonnes.

Start of welding activities: 2016.

First section completed (lower cylinder): March 2019.

Cryostat base installed in pit: Q2 2020.

Procurement responsibility: India.

Contractors: Larsen & Toubro Heavy Engineering Division, India (manufacturing design, fabrication and assembly); MAN Energy Solutions, Germany (Larsen & Toubro sub-contractor for on-site welding); SPIE Batignolles TPCI, France (Larsen & Toubro sub-contractor for the realization of the Cryostat Workshop)

In a 5,000-square-metre workshop on site, the Indian Domestic Agency is assembling the cryostat—a huge vacuum containment vessel that is also the single largest component of the ITER machine.

Completely surrounding the vacuum vessel and superconducting magnets, the 29 x 29 metre cryostat has two important roles to play—providing a vacuum environment to critical "cold" components (the magnets operating at 4.5 K and thermal shield operating at 80 K), and contributing structural reinforcement by supporting the mass of the machine and transferring horizontal and rotational forces to the radial walls.

The cryostat is a fully welded single wall stainless steel structure with a flat bottom, a rounded lid and wall thicknesses that range from 25 to 200 millimetres. A number of large openings provide access to vacuum vessel ports at three levels; others allow access for coolant pipework, cryo and current feedlines, and remote handling. Advanced welding techniques such as automated, all-position narrow groove gas tungsten arc welding have been specially developed for the fabrication of this challenging component.

Manufacturing is taking place in three stages: the fabrication of 54 segments in India; their subsequent assembly at ITER into four large sections (base, lower cylinder, upper cylinder, top lid); and the final assembly and welding of the large sections in the Tokamak Pit.

The cryostat is a vacuum-tight container that will completely surround the machine and provide an ultra-cool vacuum environment for the vacuum vessel and superconducting magnets. Welding operations are underway now on the cryostat base and lower cylinder, two of the four large sections that will be assembled and welded on site.

Cryostat segments fabricated in India are shipped according to need dates to the ITER site and stored in the Cryostat Workshop.

Beginning with the cryostat base—the first cryostat section needed in the Tokamak assembly sequence—and ending with the cryostat lid, the sections are assembled and welded on large assembly frames. These frames act both as support platforms during the welding activities and as support fixtures that interface with the transport vehicles when the time comes to move the completed components out of the workshop.

Using optical metrology techniques and strict dimensional control, operators carefully align the segments to be welded on the assembly frames. A small team of highly specialized technicians—working singly or in teams (one above, one below)—fill the gaps between each segment with weld material. Given the importance of high vacuum in the cryostat, each weld is verified through a variety of leak detection techniques.

In helium leak detection, one-metre sections of the weld to be verified are "enclosed" within leak-tight boxes positioned on opposite surfaces. Helium injected on one side of the weld can be detected—if it has filtered through a crack—by a mass spectrometer on the other side, thereby signalling a leak that must be repaired by grinding out the faulty weld and replacing it.

Three other quality assurance techniques will be used: radiographic and ultrasonic testing to detect the presence of flaws that could challenge the structural integrity of the welds, and liquid penetrant testing (LPT) for surface checks.

In total, the Indian Domestic Agency estimates that one kilometre of full penetration weld joints will have to be carried out to exacting standards for the sub-assemblies in the site workshop, followed by several hundred metres of weld joints to assemble the cryostat sections in the Tokamak Pit.

It took approximately three years (2016 to 2019) to finalize the on-site assembly and welding operations for the cryostat base—a 1,250-tonne component formed from a tier 1 "disk" and a tier 2 vertical ring and pedestal.

On an adjacent assembly platform, the less-complex lower cylinder (490 tonnes) was assembled in two years (2017 to 2019) and removed to storage on the platform to make room for the assembly of the upper cylinder, which was completed in March 2020. The steel segments required for top lid assembly are expected on site in mid-2020.

In April 2020, the 1,250-tonne cryostat base was removed to the Assembly Hall, where it will be prepared for transport by overhead crane into the bottom of the Tokamak assembly pit. This will be the official start of ITER machine assembly.

Cryostat Assembly Facts:

Number of segments fabricated in India: 54.

Sections assembled on site: cryostat base, lower cylinder, upper cylinder, top lid.

Length of weld joints for in-workshop assembly (four sections): ~ 1,015 m.

Length of weld joints for in-pit assembly: ~ 390 m.

Diameter of sections: 30 metres (approximate).

Weight of each section: base: 1,250 tonnes; lower cylinder: 490 tonnes; upper cylinder: 430 tonnes; lid: 665 tonnes.

Start of welding activities: 2016.

First section completed (lower cylinder): March 2019.

Cryostat base installed in pit: Q2 2020.

Procurement responsibility: India.

Contractors: Larsen & Toubro Heavy Engineering Division, India (manufacturing design, fabrication and assembly); MAN Energy Solutions, Germany (Larsen & Toubro sub-contractor for on-site welding); SPIE Batignolles TPCI, France (Larsen & Toubro sub-contractor for the realization of the Cryostat Workshop)

| Thread starter | Similar threads | Forum | Replies | Date |

|---|---|---|---|---|

| J | CCP downplaying India's progress for regime legitimacy | China | 130 | |

| W | US says making progress in aircraft carrier collaboration with India | Indian Navy | 6 | |

|

|

China Says Progress Being Made on India Border Talks!! | Foreign Relations | 15 | |

|

|

India lauds Sri Lanka's economic progress | Foreign Relations | 1 |

Articles

-

India Strikes Back: Operation Snow Leopard - Part 1

- mist_consecutive

- Replies: 9

-

Aftermath Galwan : Who holds the fort ?

- mist_consecutive

- Replies: 33

-

The Terrible Cost of Presidential Racism(Nixon & Kissinger towards India).

- ezsasa

- Replies: 40

-

Modern BVR Air Combat - Part 2

- mist_consecutive

- Replies: 22

-

Civil & Military Bureaucracy and related discussions

- daya

- Replies: 32