Chanakya 002

New Member

- Joined

- Aug 11, 2019

- Messages

- 272

- Likes

- 681

2025 ke baad dekhenge, abhi to 8 Tejas bhi nahi ban rahe per yearI am ready to give it an extra year. But I have my doubts..

2025 ke baad dekhenge, abhi to 8 Tejas bhi nahi ban rahe per yearI am ready to give it an extra year. But I have my doubts..

Ceramic Matrix Composite is an entire class of composite materials. GE is focusing on SiC-SiC composites. So if your question is "do we have SiC-SiC composites tech that we can apply to gas turbine engines.?", then the answer is: Not sure. In non-rotating components, such as in CFM-56 LEAP engine, maybe, if we spend some time doing R&D for it. But for use in turbine blades, defnitiely no, and not likely in the next couple of decades.Do we have that ceramic mattix composite

Shouldn't even be a question. Shinakereba naranai.I think that India should make a stategic decision whether to enter the engine manufacturing game or not

Not true. They have produced a Low Pressure Turbine and run it in a GE-414 engine. So its not as if they "haven't invested a dime." In fact, in CMC for hot sections alone, they have invested more than a Billion dollars over a period of decades. EPE is within their reach, only the funding is a problem for them. Similar to how Kaveri is within our reach, only funding is a problem. If they don't get funding for testing CMC blades in GE-414 EPE, they will most definitely get funding for testing CMC blades for an adaptive cycle engine (ADVENT) they are working on for their 6th generation fighters. They are clear on the strategic importance of gas turbine technology. India (the politicians) is not.Bro there isn’t even a prototype of the same! f414 epe is theoretically possible but they haven’t invested a dime in producing it’s components leave alone a prototype.

if they would have made even a single engine they would have been boasting about it all over the world like japan xf9 engine and Indian govt would be eager to pay and get manufacturing in India rather than ready to spend huge money in JV.

But nothing like this happening cause it doesn’t exists!

Dude what is the maximum airflow that MWF air intakes would even allow? 77 kg/sec? I think EPE requires some 85 kg/sec, which I suspect is more than what MWF intakes are being designed for. I am confused as to why GE-414 EPE is being discussed on MWF thread. I initially thought this was Kaveri engine thread.And yet it doesn't exist!.. Not even prototypes planned in foreseeable future... Hmm, ok.

Let's check again in 2030.

It was being discussed for seeing better option viability for mk2, tedbf and AMCA over indigenous engine which i don't agree with.Ceramic Matrix Composite is an entire class of composite materials. GE is focusing on SiC-SiC composites. So if your question is "do we have SiC-SiC composites tech that we can apply to gas turbine engines.?", then the answer is: Not sure. In non-rotating components, such as in CFM-56 LEAP engine, maybe, if we spend some time doing R&D for it. But for use in turbine blades, defnitiely no, and not likely in the next couple of decades.

Shouldn't even be a question. Shinakereba naranai.

Not true. They have produced a Low Pressure Turbine and run it in a GE-414 engine. So its not as if they "haven't invested a dime." In fact, in CMC for hot sections alone, they have invested more than a Billion dollars over a period of decades. EPE is within their reach, only the funding is a problem for them. Similar to how Kaveri is within our reach, only funding is a problem. If they don't get funding for testing CMC blades in GE-414 EPE, they will most definitely get funding for testing CMC blades for an adaptive cycle engine (ADVENT) they are working on for their 6th generation fighters. They are clear on the strategic importance of gas turbine technology. India (the politicians) is not.

Fun fact: There are at least three Indian Americans involved in this endeavour. If GoI were Chinese, they would have paid these three Indian Americans handsomely to come back to India and work on these things here.

Dude what is the maximum airflow that MWF air intakes would even allow? 77 kg/sec? I think EPE requires some 85 kg/sec, which I suspect is more than what MWF intakes are being designed for. I am confused as to why GE-414 EPE is being discussed on MWF thread. I initially thought this was Kaveri engine thread.

Depends on:-It was being discussed for seeing better option viability for mk2, tedbf and AMCA over indigenous engine which i don't agree with.

Great explanation.

Bro don't get me started on hundred more issues. Thread will move off topic. MWF should have indigenous engine in first engine overhaul. Atleast as per my opinion.Depends on:-

If they want to give us this engine (assuming they fund its development for their F-18 or we fund it)

If our air intakes can allow sufficient airflow

If we have truly given up on making India Atmanirbhar in jet engines and if we trust the untrustworthy Americans.

Correct me if I’m wrong!Not true. They have produced a Low Pressure Turbine and run it in a GE-414 engine. So its not as if they "haven't invested a dime." In fact, in CMC for hot sections alone, they have invested more than a Billion dollars over a period of decades. EPE is within their reach, only the funding is a problem for them. Similar to how Kaveri is within our reach, only funding is a problem. If they don't get funding for testing CMC blades in GE-414 EPE, they will most definitely get funding for testing CMC blades for an adaptive cycle engine (ADVENT) they are working on for their 6th generation fighters. They are clear on the strategic importance of gas turbine technology. India (the politicians) is not.

I wish GOI was that smart!Fun fact: There are at least three Indian Americans involved in this endeavour. If GoI were Chinese, they would have paid these three Indian Americans handsomely to come back to India and work on these things here.

No. As far as I know, CMC turbines have never been used before GE-414 EPE. Not sure what the turbine entry temperature of YF120 was, but I doubt it was 2000 degrees Celsius. Even CMC blades are barely reaching 1800 degrees.Correct me if I’m wrong!

The CMC tech they have acquired is actually from yf120 & yf136 where they are able to take the core temp to just below 2000C. They were even adaptive cycle engines.

Not exactly. F-35 has a better engine than F-22. Moreover, they are made by different companies. So its not as if they "milked" other countries for the engine. Though they did for the jet itself. USA did fund the development for F-35's engine.f414 epe is more like f35 where they milked other countries in it development!

USA made f22 for sure they could make f35.

but in the process what they did is the reason Indian government and me hesitant about them thus RR & DRDO JV is what I’m looking forward to!

Thanks for this source. I didn't know they've already achieved 1982 Celsius in F-35 engines. This is defnitiely a lot higher than F-22 engines. I thought F-35 engines have a better thrust to weight ratio than F-22 engines due to the absence of stators and counter-rotating blade design of F-35 engines. But this TET is mind-blowing.Even I’m not 100% but you can check pw135 core temperature is acknowledged to be 3600F(1982C) which makes me believe it to be using CMC as nothing else can with that!

check this research paper!

https://asmedigitalcollection.asme....0/Fahrenheit-3-600Everywhere-You-Look-the-Gas

Even I’m not 100% but you can check pw135 core temperature is acknowledged to be 3600F(1982C) which makes me believe it to be using CMC as nothing else can with that!

check this research paper!

https://asmedigitalcollection.asme....0/Fahrenheit-3-600Everywhere-You-Look-the-Gas

Just a clarification, should have included it in original post, TET is a function of not only blade material but also of the TBC and additional film cooling that is applied over Nickel superalloy blades. F-35's engine is able to achieve a high TET of 1982 Celsius, but a CMC blade trying to achieve the same will not have the help of film cooling (which is not being planned for CMC blades). So whatever generation single crystal Ni Superalloy was used in F-35 engine, it likely can't withstand temperatures in excess of 1800 Celsius without film cooling. Meanwhile, CMC blades at 1982 Celsius will have to directly withstand that temperature without the film cooling.Thanks for this source. I didn't know they've already achieved 1982 Celsius in F-35 engines. This is defnitiely a lot higher than F-22 engines. I thought F-35 engines have a better thrust to weight ratio than F-22 engines due to the absence of stators and counter-rotating blade design of F-35 engines. But this TET is mind-blowing.

.

However, I do remember reading that CMC blades have managed to achieve 1800 Celsius. GE has only tested CMC blades in Low Pressure Turbine, not in High Pressure Turbine. So maybe the work for producing a CMC blade for achieving more than 2000 degrees Celsius TET is still on. That may be why they still need more funding. But its only a matter of time before they get it. Makes me wonder what drastic increase in TET they are planning for their 6th gen fighter engines.

Don't get it. If Kaveri is within reach then why don't we fund it over spending $16-20 billion (figure from BRF) for RR/Safran engine coming in 10 years?Kaveri is within our reach, only funding is a problem

We need a better engine now than Kaveri's original specs. Focus is on getting an engine for AMCA and there is a time limit of 2025 for developing this engine. I still think that even such an engine is achievable on our own, but not going for a JV with a foreign partner now would be risky. Even Saurav Jha has been saying that regardless of what we do as JV, we need to have (in-parallel) a national mission on Jet Engines similar to how we were laser focussed on missile technology (IGMDP and follow up programs). But GoI, in all their wisdom is deciding against it. Just like they made the decision to not fund that IISc professor's Gallium Nitride fab.Don't get it. If Kaveri is within reach then why don't we fund it over spending $16-20 billion (figure from BRF) for RR/Safran engine?

A thermal & environmental coating is applied in CMC blades aswell.Just a clarification, should have included it in original post, TET is a function of not only blade material but also of the TBC and additional film cooling that is applied over Nickel superalloy blades. F-35's engine is able to achieve a high TET of 1982 Celsius, but a CMC blade trying to achieve the same will not have the help of film cooling (which is not being planned for CMC blades). So whatever generation single crystal Ni Superalloy was used in F-35 engine, it likely can't withstand temperatures in excess of 1800 Celsius without film cooling. Meanwhile, CMC blades at 1982 Celsius will have to directly withstand that temperature without the film cooling.

We need a better engine now than Kaveri's original specs

2025? It is planned by 2031-32. JV is fail safe as RR most probably will make sure its done in timeline.We need a better engine now than Kaveri's original specs. Focus is on getting an engine for AMCA and there is a time limit of 2025 for developing this engine. I still think that even such an engine is achievable on our own, but not going for a JV with a foreign partner now would be risky. Even Saurav Jha has been saying that regardless of what we do as JV, we need to have (in-parallel) a national mission on Jet Engines similar to how we were laser focussed on missile technology (IGMDP and follow up programs). But GoI, in all their wisdom is deciding against it. Just like they made the decision to not fund that IISc professor's Gallium Nitride fab.

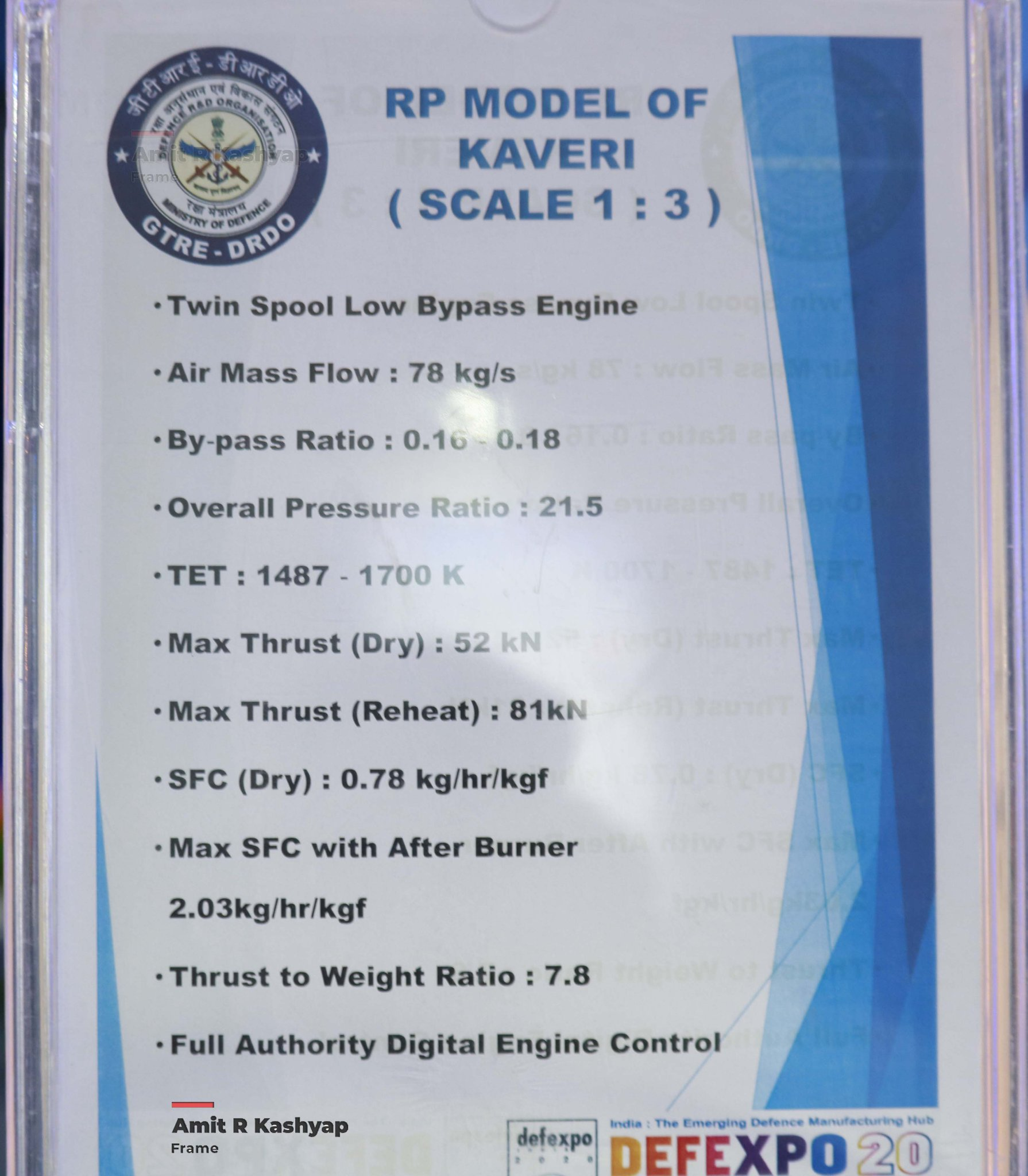

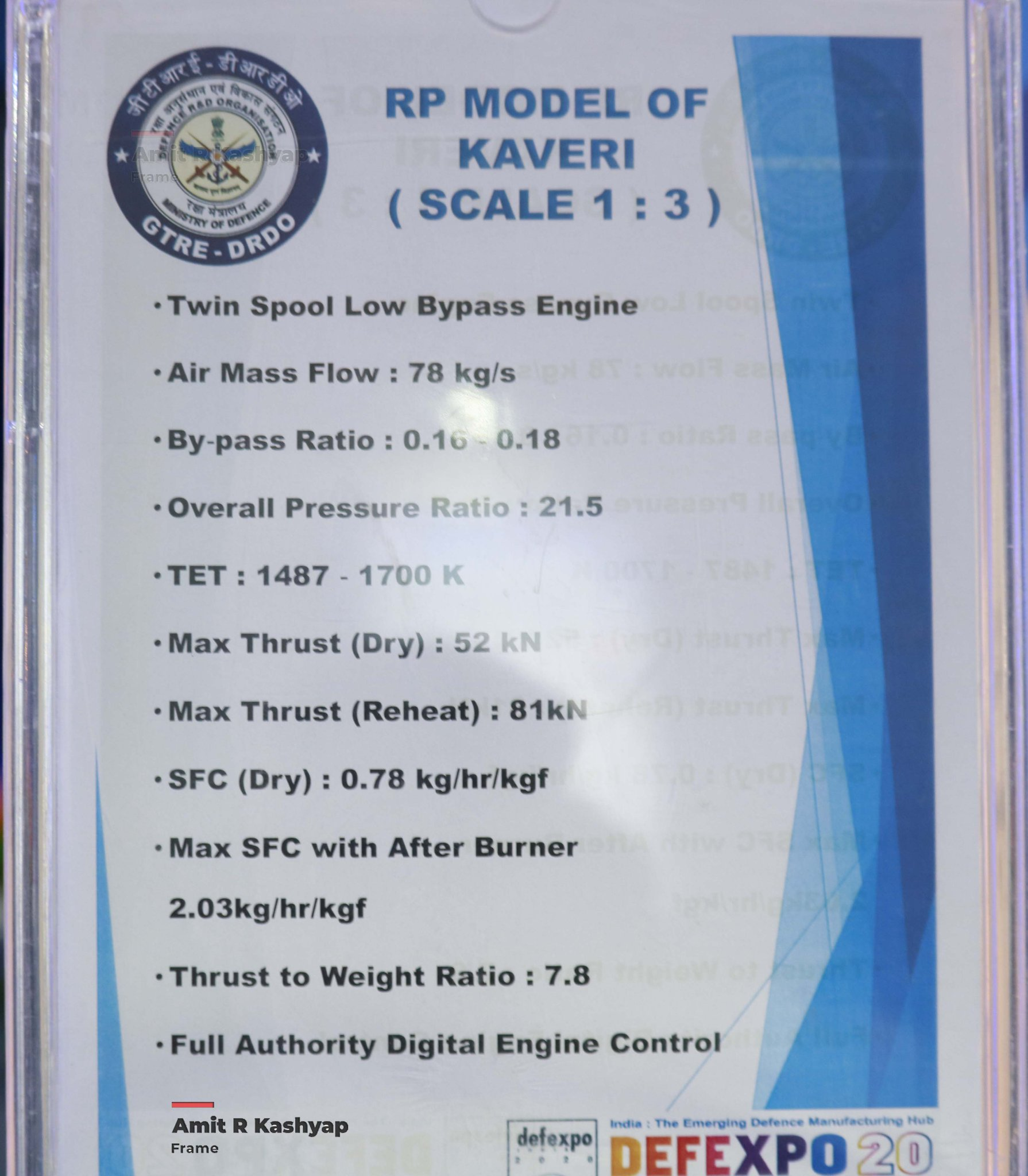

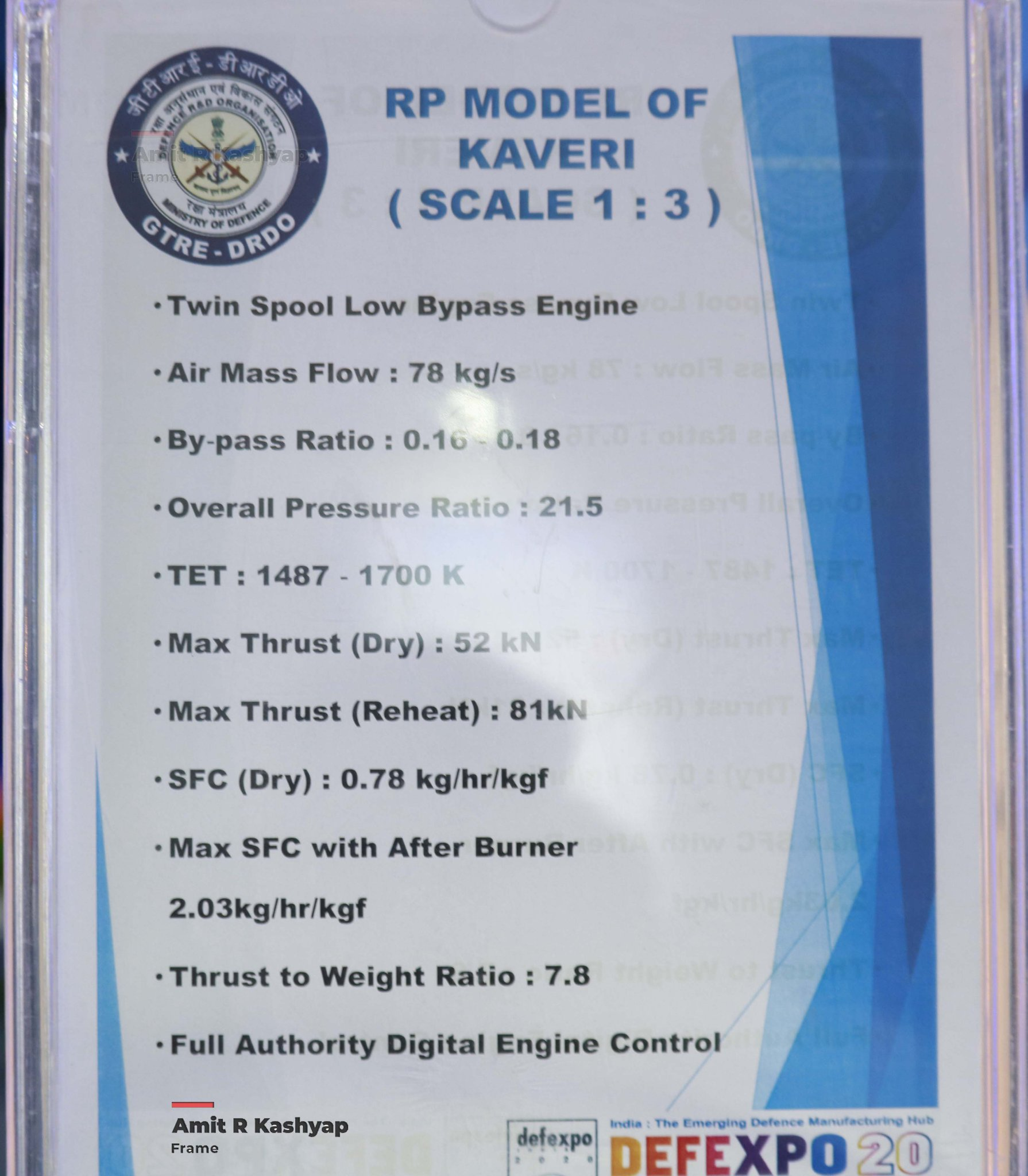

Thrust is low and weight is high with current engine.

If we can still get these paper specs in a quality jet engine that we own fully- can't we fit it into Tejas Mk1/Mk1As given each fighter uses 3.5 engines over its lifetime. There is still a market for the original Kaveri over the next 40 years.

Not really bro!

If we can still get these paper specs in a quality jet engine that we own fully- can't we fit it into Tejas Mk1/Mk1As given each fighter uses 3.5 engines over its lifetime. There is still a market for the original Kaveri over the next 40 years.

The Environmental Barrier Coating of CMC blades is similar to Thermal Barrier Coating applied in Ni Superalloys. Film cooling is over and above that. I remember reading that they are skipping film cooling in CMC blades (don't remember the reason why). So I was saying that the film cooling is missing, not the coating.A thermal & environmental coating is applied in CMC blades aswell.

SiC based CMC are the same used in Japan’s XF9 engines!

please check i read somewhere they are able to withstand 2000C and due to their low density compared to nickel alloys they could potentially result in T/W ratio of 12-15.

GoI is content with GE engines for now and want to spend all money on JV for AMCA engines. Well, its not like GTRE is sitting idle either. But they are underfunded and out of time. They are also focusing on dry version of Kaveri for UCAV. Not sure if they are still trying to solve the reheat oscillation problem given their limited time, funding, facilities and manpower.

If we can still get these paper specs in a quality jet engine that we own fully- can't we fit it into Tejas Mk1/Mk1As given each fighter uses 3.5 engines over its lifetime. There is still a market for the original Kaveri over the next 40 years.

My bad. I meant 2035, not 2025.2025? It is planned by 2031-32. JV is fail safe as RR most probably will make sure its done in timeline.

| Thread starter | Similar threads | Forum | Replies | Date |

|---|---|---|---|---|

|

|

ADA Tejas Mark-II/Medium Weight Fighter | Knowledge Repository | 6 | |

|

|

AERO INDIA 2021 | Science and Technology | 308 | |

|

|

ADA Tejas (LCA) News and Discussions | Indian Air Force | 17457 | |

| P | ADA DRDO and HAL Delays a threat to National Security | Internal Security | 20 |