Kaveri Engine

- Thread starter natarajan

- Start date

More options

Who Replied?INDIAFIRST

New Member

- Joined

- May 13, 2018

- Messages

- 396

- Likes

- 1,749

a beautiful explanation of jet engine and where we lag

[YOUTUBE]

[YOUTUBE]

- Joined

- Oct 14, 2020

- Messages

- 28,260

- Likes

- 195,943

Yet can’t fructify Kaveri

Blank

New Member

- Joined

- Jan 23, 2021

- Messages

- 906

- Likes

- 6,384

Indigenously developed powders from unused scrape materials to be used for the repair of aero-engine components made of Ni-based super alloy

Indian Scientists have for the first time repaired aero-engine components through emerging additive

pib.gov.in

Indigenously developed powders from unused scrape materials to be used for the repair of aero-engine components made of Ni-based super alloy

Kalkioftoday

New Member

- Joined

- Nov 20, 2020

- Messages

- 327

- Likes

- 1,838

Buddy, honestly speaking there is not much we know about kaveri's current progress and problems. Most of the things here you see are just speculation. So don't expect a concrete answer to your questionAny good reason why the Kabini core is not being made into a GE TF34 type turbofan? I may have missed some info on this.

- Joined

- Jan 14, 2020

- Messages

- 9,609

- Likes

- 84,139

Harvesting all the learnings of small engines and co-development, today the R&D unit of HAL, AERDC (Aero Engine Research and Design Centre) is tasked to develop two prestigious engines namely; Hindustan Turbo Fan engine (HTFE-25) of 25 kN thrust which can power trainer aircraft, UAV’s, Twin engine small fighter aircraft or regional jets and Hindustan Turbo Shaft engine (HTSE-1200) of shaft power rating which can power Light & Medium weight helicopters (3.5 to 6.5 tonnes in single/ twin engine configuration)

Significant progress has been made in both the projects with successful trial runs of 25 kN core engine and 1200 kW Jet mode version engine up to 100% RPM. HAL is confident of achieving the targeted design parameters and productionising these engines.

However the challenges are many in aero engine design like:

The HTFE-25 and HTSE-1200 engine programs, both of which are in prototype evaluation phase are loaded with some of the concurrent technologies like High Pressure Compressor, Effusion cooled combustor, SX Blades, 3D printed parts, laser shock peening, FADEC, Atomizers, High speed Gearbox etc. In parallel, futuristic developments in technology are also in progress, like Afterburner on PTAE and HTFE, Flame propagating nozzles, EHSV and Stepper motor based FMUs etc.

On the material and processes front, HAL is developing SX blades with DMRL for HTSE-1200 engine program. The coating by EBPVD method is also being established with ARCI Hyderabad to be utilized on SX blades. The process has been proven on sample blades. Similarly the Laser shock peening will be utilized through Coventry University UK. We are developing atomizers with IISc.

HAL is constantly imparting knowledge to its work force for training its manpower. It is trying to keep abreast with the latest happenings in the field by joining hands with inland and foreign universities like IITs, IISc, Cranfield University etc.

HAL is utilizing the established but limited facilities at NAL, GTRE and other DRDO labs for testing combustor, gas generator turbine, electronic components etc. However we do not have the facilities in the country to test compressors, HP turbines, power turbines of the order of 1 MW and above with matching speeds. Flying test bed and altitude test benches are the two major facilities which have to be established on case to case basis, which demand an investment of the order of 1500+ Crores. These facilities are expected to be established under the proposed AERO ENGINE COMPLEX by MoD as National Test Facilities.

On establishing and handholding the MSMEs, HAL is providing opportunities to be partners in development. There are 70+ vendors with AERDC-HAL which are exclusively sensitized for engine development. They are onboard in the development stage itself so that there can be a smooth transition to production stage.

Significant progress has been made in both the projects with successful trial runs of 25 kN core engine and 1200 kW Jet mode version engine up to 100% RPM. HAL is confident of achieving the targeted design parameters and productionising these engines.

However the challenges are many in aero engine design like:

- Funding challenges

- Technological challenges

- Trained man power specific to aviation industry

- Testing facilities from component test facility to Flying Test bed

- Precision manufacturing and established Vendor base etc.

The HTFE-25 and HTSE-1200 engine programs, both of which are in prototype evaluation phase are loaded with some of the concurrent technologies like High Pressure Compressor, Effusion cooled combustor, SX Blades, 3D printed parts, laser shock peening, FADEC, Atomizers, High speed Gearbox etc. In parallel, futuristic developments in technology are also in progress, like Afterburner on PTAE and HTFE, Flame propagating nozzles, EHSV and Stepper motor based FMUs etc.

On the material and processes front, HAL is developing SX blades with DMRL for HTSE-1200 engine program. The coating by EBPVD method is also being established with ARCI Hyderabad to be utilized on SX blades. The process has been proven on sample blades. Similarly the Laser shock peening will be utilized through Coventry University UK. We are developing atomizers with IISc.

HAL is constantly imparting knowledge to its work force for training its manpower. It is trying to keep abreast with the latest happenings in the field by joining hands with inland and foreign universities like IITs, IISc, Cranfield University etc.

HAL is utilizing the established but limited facilities at NAL, GTRE and other DRDO labs for testing combustor, gas generator turbine, electronic components etc. However we do not have the facilities in the country to test compressors, HP turbines, power turbines of the order of 1 MW and above with matching speeds. Flying test bed and altitude test benches are the two major facilities which have to be established on case to case basis, which demand an investment of the order of 1500+ Crores. These facilities are expected to be established under the proposed AERO ENGINE COMPLEX by MoD as National Test Facilities.

On establishing and handholding the MSMEs, HAL is providing opportunities to be partners in development. There are 70+ vendors with AERDC-HAL which are exclusively sensitized for engine development. They are onboard in the development stage itself so that there can be a smooth transition to production stage.

- Joined

- Jan 14, 2020

- Messages

- 9,609

- Likes

- 84,139

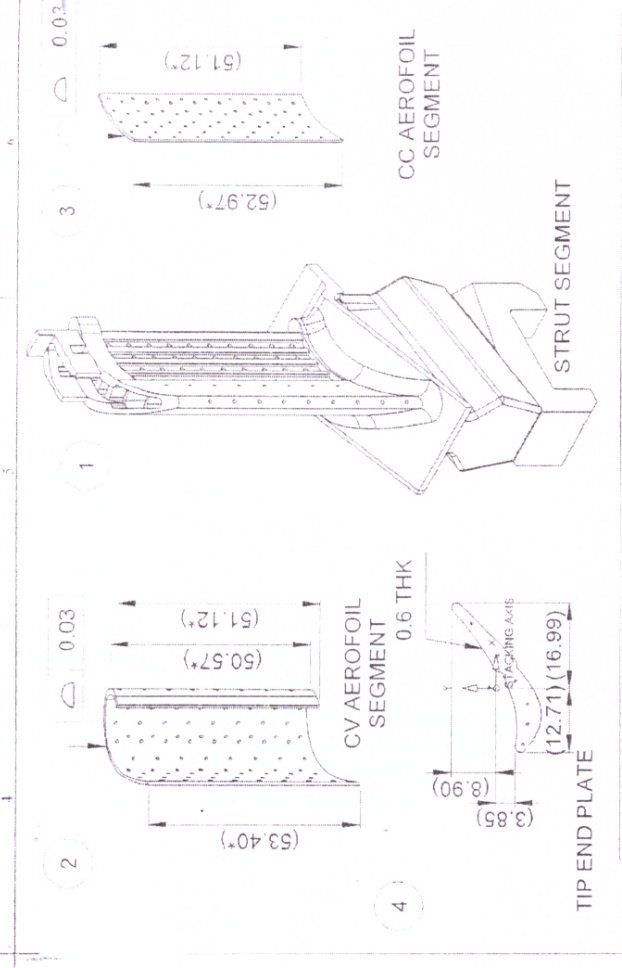

Cooled single crystal blade.

JBH22

New Member

- Joined

- Jul 29, 2010

- Messages

- 6,554

- Likes

- 18,090

Mechanic can service thousand cars, but that does not mean he will launch his own production facility.Yet can’t fructify Kaveri

- Joined

- Oct 14, 2020

- Messages

- 28,260

- Likes

- 195,943

Kalkioftoday

New Member

- Joined

- Nov 20, 2020

- Messages

- 327

- Likes

- 1,838

MonaLazy

New Member

- Joined

- Aug 12, 2019

- Messages

- 1,321

- Likes

- 7,898

IR presenting a picture of reality & a feasible way ahead:

How close and how far! Is it metallurgy or overall design optimisation! What’s lacking? Appreciate

@Indrani1_Roy throw some light for us.

Oh. Entering this with much reluctance. As I have said before, I feel completely technically unqualified to say what we need to do get going on Kaveri-deriavatives going. The following page scratches the surface of technical issues.

First thing, I do want to say: aam jingoes don't appreciate the complexity of modern low bypass turbofan (LBTF) engine. It is not a stretch to say that it is more difficult than rocket engines. Just compare the number of rocket vs LBTF engines designed in the last 3 decades.

Many people think that privatization is the panacea. But that doesn't solve this riddle. Bharat Forge has tried to build a 4kN engine for the past 5 years. Mahindra tried to turn around GippsAero by just stretching the GA-8 by a mtr. Did not work. Both are excellent companies!

The "free-market is the solution to everything" junta also fail in the basic understanding of this business: But an LBTF engine by itself is financially unviable. But first, let me give you an example where it can work.

GoI says that it will mandate all domestic operators to buy a certain percentage of their fleet as the RTA. That leads to say a guaranteed orders of say 200 aircraft. It opens up a competition to dev such an aircraft where two top contenders split the orders in a 60:40 ratio.

Development cost will be around ~$500 M. Each aircraft costs about $30M. So, that's business worth $1.8B & $1.2B respectively. Players might come forward.

Now, let's take a 110 kN engine. Such an engine will cost $10 million. Let's say India will place an order for 1000 engines. That's $10 billion. The development cost of such an engine is a few times that!!! So why will a private sector company come forward?

Modern LBTF DnD is not in the ambit of large corporations, but of large countries. For example, whole of EU is pitching together to field a next gen engine. And they already have significant know-how, know-why and infra. Are the Europeans incapable?!! Surely not.

Let me ask this question in another way: If China is offered complete knowhow and know-why of building a state of the art 130 kN engine for $50B dollars, do you think China will take it? Albeit they would. They have already spend more than that.

The tuth is world class LBTF requires world classe infrastructure, know-how and know-why which takes decades and 10s-100s of billions in investment. The GOI doesn't have the appetite to buy that strategic independence. It doesn't buy any votes 5 years from now!

So, then is there no way for us. I want to believe there is. But I have several questions. Are we as a nation serious enough? Are we realistic enough? Are we patient enough? Are we structured enough? Are we disciplined enough? Have we learned enough (through Kaveri)?

I seek forgiveness for giving advise way outside my depth. But these are my observations. The aero development in our country is fractured. HAL, GTRE, ADA, NAL & private sector don't even come under the same ministry! How are we going to foot the bill for an LBTF?

We need to unite as a nation. We need a 'Sarabhai' who is knowledgeable, rational and is provided complete autonomy (reports directly to the PM). All players have to be asked hard questions & the country must understand that a world class engine in 10 years is not possible.

To GTRE we must ask: What is the basis for confidence in building a greater than >9:1 thrust engine in 10 years? Kaveri has been flight tested for a sum total of few hours?! IAF: Don't ask for an engine that US/EU/Russia can produce today. It's not possible.

The goal would be to develop a core 3 engines around the same core (for maximum ROI, learning and minimizing risk) a. 60kN High bypass ratio (HBPR) engine b. 35kN Low bypass non after burning (LBPR) engine c. 50kN Low bypass after burning (LBPR-AB) engine.

Ask all the design houses to consolidate around these engines. HBPR goes for RTA. LBPR goes for AJTs and drones. 1xLBPR-AB goes for LIFT, 2xLBPR-AB goes for adapted LCA Mk3. AMCA has to be based on foreign engines till the second generation of engines come by.

By the way, this is the way Japan took. F3 was their first engine (roughly equivalent to our HTFE) used in AJTs. XF-5 is their LBPR-AB equivalent. 2 of these powered the 5th-gen X-2 prototype. One can imagine an F5-IIe class LIFT/fighter powered by a single XF-5.

The F7 is their HBPR which powers their Kawasaki P-1 aircraft. The next step is the XF9 two of which will power their NG F-X fighter. End of thread.

How close and how far! Is it metallurgy or overall design optimisation! What’s lacking? Appreciate

@Indrani1_Roy throw some light for us.

Oh. Entering this with much reluctance. As I have said before, I feel completely technically unqualified to say what we need to do get going on Kaveri-deriavatives going. The following page scratches the surface of technical issues.

First thing, I do want to say: aam jingoes don't appreciate the complexity of modern low bypass turbofan (LBTF) engine. It is not a stretch to say that it is more difficult than rocket engines. Just compare the number of rocket vs LBTF engines designed in the last 3 decades.

Many people think that privatization is the panacea. But that doesn't solve this riddle. Bharat Forge has tried to build a 4kN engine for the past 5 years. Mahindra tried to turn around GippsAero by just stretching the GA-8 by a mtr. Did not work. Both are excellent companies!

The "free-market is the solution to everything" junta also fail in the basic understanding of this business: But an LBTF engine by itself is financially unviable. But first, let me give you an example where it can work.

GoI says that it will mandate all domestic operators to buy a certain percentage of their fleet as the RTA. That leads to say a guaranteed orders of say 200 aircraft. It opens up a competition to dev such an aircraft where two top contenders split the orders in a 60:40 ratio.

Development cost will be around ~$500 M. Each aircraft costs about $30M. So, that's business worth $1.8B & $1.2B respectively. Players might come forward.

Now, let's take a 110 kN engine. Such an engine will cost $10 million. Let's say India will place an order for 1000 engines. That's $10 billion. The development cost of such an engine is a few times that!!! So why will a private sector company come forward?

Modern LBTF DnD is not in the ambit of large corporations, but of large countries. For example, whole of EU is pitching together to field a next gen engine. And they already have significant know-how, know-why and infra. Are the Europeans incapable?!! Surely not.

Let me ask this question in another way: If China is offered complete knowhow and know-why of building a state of the art 130 kN engine for $50B dollars, do you think China will take it? Albeit they would. They have already spend more than that.

The tuth is world class LBTF requires world classe infrastructure, know-how and know-why which takes decades and 10s-100s of billions in investment. The GOI doesn't have the appetite to buy that strategic independence. It doesn't buy any votes 5 years from now!

So, then is there no way for us. I want to believe there is. But I have several questions. Are we as a nation serious enough? Are we realistic enough? Are we patient enough? Are we structured enough? Are we disciplined enough? Have we learned enough (through Kaveri)?

I seek forgiveness for giving advise way outside my depth. But these are my observations. The aero development in our country is fractured. HAL, GTRE, ADA, NAL & private sector don't even come under the same ministry! How are we going to foot the bill for an LBTF?

We need to unite as a nation. We need a 'Sarabhai' who is knowledgeable, rational and is provided complete autonomy (reports directly to the PM). All players have to be asked hard questions & the country must understand that a world class engine in 10 years is not possible.

To GTRE we must ask: What is the basis for confidence in building a greater than >9:1 thrust engine in 10 years? Kaveri has been flight tested for a sum total of few hours?! IAF: Don't ask for an engine that US/EU/Russia can produce today. It's not possible.

The goal would be to develop a core 3 engines around the same core (for maximum ROI, learning and minimizing risk) a. 60kN High bypass ratio (HBPR) engine b. 35kN Low bypass non after burning (LBPR) engine c. 50kN Low bypass after burning (LBPR-AB) engine.

Ask all the design houses to consolidate around these engines. HBPR goes for RTA. LBPR goes for AJTs and drones. 1xLBPR-AB goes for LIFT, 2xLBPR-AB goes for adapted LCA Mk3. AMCA has to be based on foreign engines till the second generation of engines come by.

By the way, this is the way Japan took. F3 was their first engine (roughly equivalent to our HTFE) used in AJTs. XF-5 is their LBPR-AB equivalent. 2 of these powered the 5th-gen X-2 prototype. One can imagine an F5-IIe class LIFT/fighter powered by a single XF-5.

The F7 is their HBPR which powers their Kawasaki P-1 aircraft. The next step is the XF9 two of which will power their NG F-X fighter. End of thread.

MonaLazy

New Member

- Joined

- Aug 12, 2019

- Messages

- 1,321

- Likes

- 7,898

If a 110kN engine is so difficult for a vitamin M deficient country like us why don't we fund the EPE? $3B to see it materialize (with obviously no IP for us) is a pittance compared to the $50B ask for complete know-how and know why. Will be production-ready in 3-4 years after all certifications and being a drop-in replacement for vanilla 414 can boost all round capabilities of Mk2, AMCA & TEDBF from the first plane of the first squadron. Don't have to wait for MLU to plonk in the Indian 110kN if & when that materialises.IR presenting a picture of reality & a feasible way ahead

Additionally, the 414 will be manufactured locally. Makes sense from that PoV also to manufacture the EPE version. Can be exported and maintained from India for the globe (several current and future planes to be built around GE 414)- lower price per unit and the foreign sales can offset a lot of the costs.

Also since we have the exact engine IAF wants much earlier in time- the $50B for own 110kN can be spread out over say 10 more years into the future. That track must not be killed, but every other program should not depend on it's absolute success. De-risk AMCA, as there is no need for an up-engined Mk2 only add capability for Manned-Unmanned missions in Mk2 & the Indian engine if ready by then.

Not exactly a fan of trucking with Uncle Sam- would have preferred a middling power like France or Britain- but that choice of GE 404/414 has already been made.

@ezsasa @hit&run we need a new thread for this 110kN engine- since it is not Kaveri but a clean-sheet design. Otherwise please move posts to a more appropriate thread (AMCA maybe?).

Last edited:

Plz delete this if not related to thread or doing violation of terms. I posted hastily

Vamsi

New Member

- Joined

- Jun 27, 2020

- Messages

- 4,858

- Likes

- 29,461

We should not invest in EPE , why? the answer is very simple, why should we should invest in uncle Sam's engine who will backstabb us at any time , also why should we invest in an engine if we don't get any know how and know why and IP rights.If a 110kN engine is so difficult for a vitamin M deficient country like us why don't we fund the EPE? $3B to see it materialize (with obviously no IP for us) is a pittance compared to the $50B ask for complete know-how and know why. Will be production-ready in 3-4 years after all certifications and being a drop-in replacement for vanilla 414 can boost all round capabilities of Mk2, AMCA & TEDBF from the first plane of the first squadron. Don't have to wait for MLU to plonk in the Indian 110kN if & when that materialises.

Additionally, the 414 will be manufactured locally. Makes sense from that PoV also to manufacture the EPE version. Can be exported and maintained from India for the globe (several current and future planes to be built around GE 414)- lower price per unit and the foreign sales can offset a lot of the costs.

Also since we have the exact engine IAF wants much earlier in time- the $50B for own 110kN can be spread out over say 10 more years into the future. That track must not be killed, but every other program should not depend on it's absolute success. De-risk AMCA, as there is no need for an up-engined Mk2 only add capability for Manned-Unmanned missions in Mk2 & the Indian engine if ready by then.

Not exactly a fan of trucking with Uncle Sam- would have preferred a middling power like France or Britain- but that choice of GE 404/414 has already been made.

@mods we need a new thread for this 110kN engine- since it is not Kaveri but a clean-sheet design. Otherwise please move posts to a more appropriate thread (AMCA maybe?).

Also 414 won't be manufactured entirely in Bharat, it's just screwdriver giri

MonaLazy

New Member

- Joined

- Aug 12, 2019

- Messages

- 1,321

- Likes

- 7,898

Yes, turboshaft engines for ALH Dhruv & LUH materialized thanks to HAL's partnership with Safran. They have also taken the closest look yet at Kaveri for any outsider and know exactly where we are in jet engine tech.

France is any day better than US or UK as a strategic partner- going purely by their track record France has exhibited a mostly independent foreign policy.

Let's just ignore the Mistrals for Russia.

Articles

-

India Strikes Back: Operation Snow Leopard - Part 1

- mist_consecutive

- Replies: 9

-

Aftermath Galwan : Who holds the fort ?

- mist_consecutive

- Replies: 33

-

The Terrible Cost of Presidential Racism(Nixon & Kissinger towards India).

- ezsasa

- Replies: 40

-

Modern BVR Air Combat - Part 2

- mist_consecutive

- Replies: 22

-

Civil & Military Bureaucracy and related discussions

- daya

- Replies: 32