ISRO General News and Updates

- Thread starter rahulrds1

- Start date

More options

Who Replied?Karthi

New Member

- Joined

- Jul 15, 2018

- Messages

- 2,214

- Likes

- 17,755

Indian Private Startup Manastu, along with the Indian Institute of Technology, Bombay (IIT Bombay), has indigenously developed a hydrogen peroxide based green propulsion technology.

In satellites and spacecraft, propulsion is achieved through a thruster. This thruster works on the principles of a rocket engine. The key difference is that of the propellant, and hence the internal thruster design.

Hydrogen peroxide undergoes catalytic decomposition, releasing water vapour, oxygen and heat. At higher temperatures, additives combusts in the presence of oxygen, generating even higher temperature.

A crucial component governing the performance and life of a thruster is the catalyst. Manastu Space has invented a proprietary high temperature catalyst which can effectively decompose hydrogen peroxide, withstand high temperatures and thermal stresses.

Advantages of HPHC Green Propulsion Over Existing.

30% weight reduction in propulsion system due to higher performance

40 Times Less Toxic -Non carcinogenic and reduced toxicity helps reduced cost of operations by 60%

25% Higher Performance - Use of hydrocarbon overcomes the earlier disadvantage of the hydrogen peroxide

Simplicity and Reliability-Due to monopropellant system, number components reduces drastically allowing greater reliability

Resurgence of Hydrogen Peroxide.

Apart from the advantages of higher performance and lower toxicity, hydrogen peroxide has an added advantage of space heritage. In the pre-hydrazine era, hydrogen peroxide was extensively used in satellite and rocket technology. Due to its low performance and unreliable catalyst of the hydrazine, hydrogen peroxide was eventually phased out. Due to the need of safe alternative to highly toxic hydrazine, advancements in the materials and catalysts, hydrogen peroxide is re-emerging. One other reason of resurgence of the HP is extensive test data, detailed properties and space heritage. Storability of the highly concentrated hydrogen peroxide has been proven time and time again.

Areas Of Applications

Satellite Propulsion

Lander Propulsion System for Interplanetary Missions

Reaction Control System For Rockets And Missiles

Launch Vehicle Propulsion System

Liquid Apogee Motor for Satellites

- Joined

- Jan 14, 2020

- Messages

- 9,609

- Likes

- 84,139

shukrayaan ........................

- Joined

- Jan 14, 2020

- Messages

- 9,609

- Likes

- 84,139

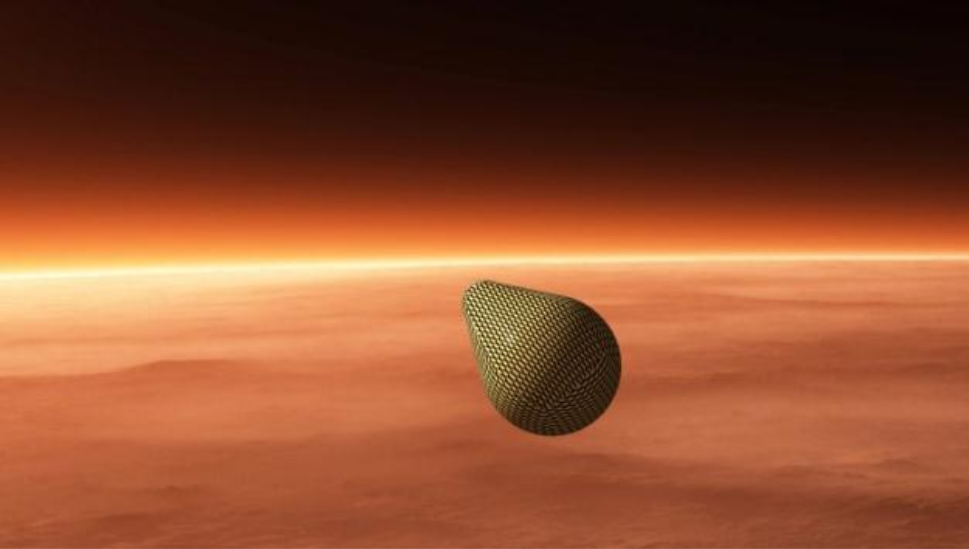

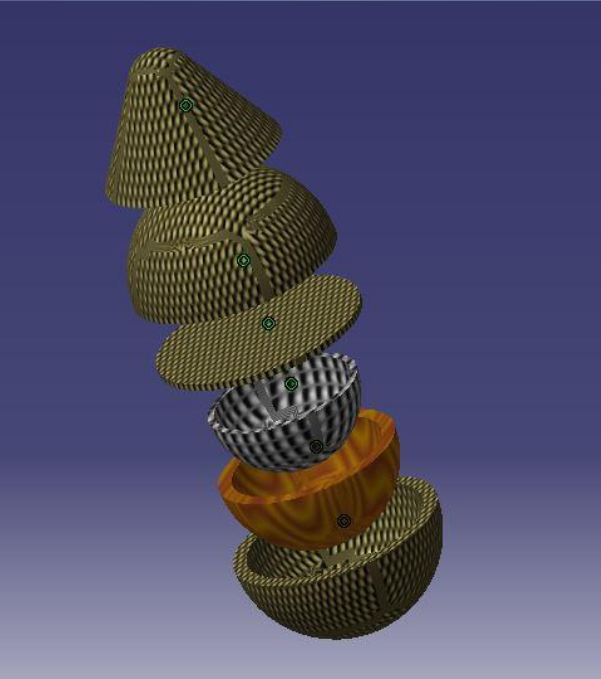

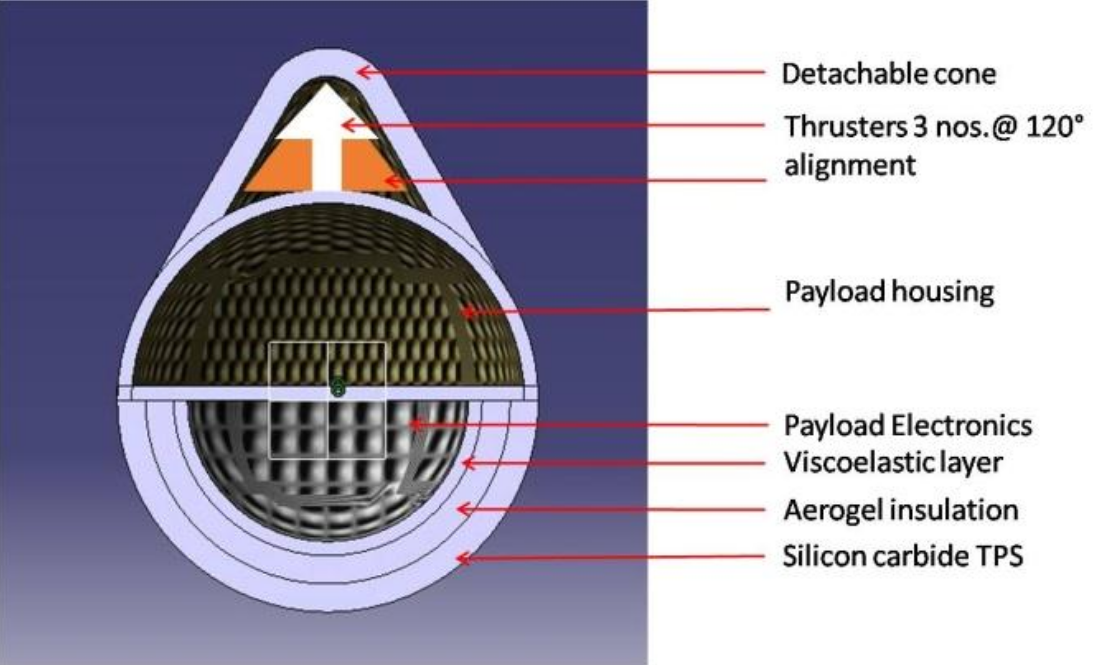

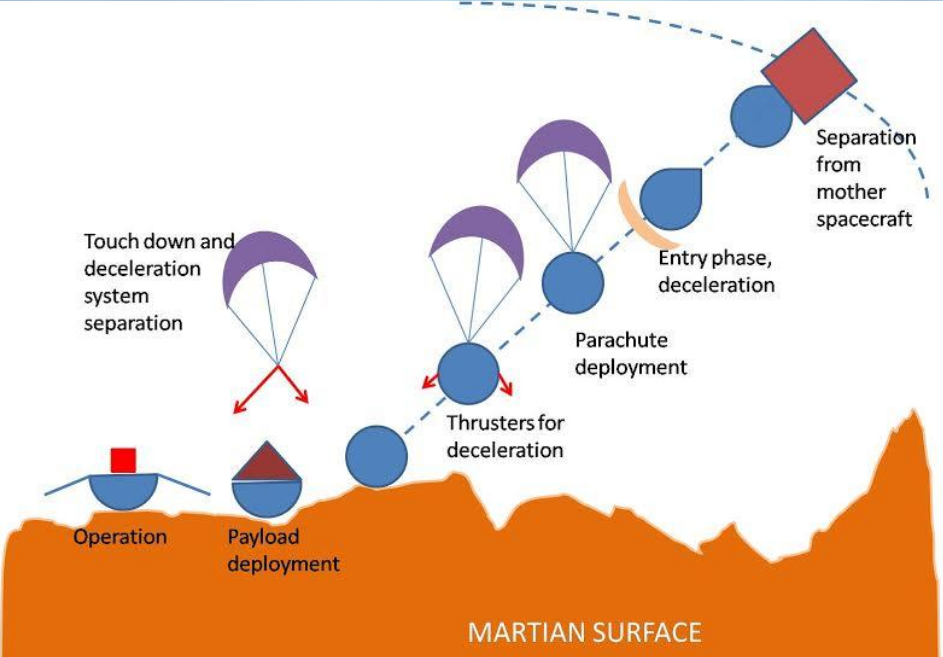

IAD stands for Inflatable Aerodynamic Decelerator, otherwise known as Aerodynamic Decelerator Atmospheric-entry Module (ADAM). The system is being designed jointly by VSSC and IIST for deployment off of a Mars orbiter. More about ADAM :

- ADAM is an atmospheric entry module that delivers safely micro/mini probes/payloads to Martian surface, weighing from minimum 5 kg to 15 kg net weight relevant for small scale researchers and explorers.

- Conceptualized as a stretched sphere (tear drop shape during its atmospheric entry) and the rear cone separates out during the parachute deployment transforming the module to a sphere.

- This sphere drops down decelerating, aided with three thrusters to bring down the velocity to near zero value for a safer touchdown.

- Visco-elastic damping materials serves as shock absorbers to prevent impact load transfer to the payload inside.

- Outer aeroshell in the shape of a stretched sphere (tear drop shape)

- Multiple layer of Thermal Protection System (TPS)

- Visco-elastic shock absorbing layer

- Decelerator system consisting of parachute and thrusters

- Concept is analogous to advent of mini-satellites when larger spacecrafts of agencies reign the space arena.

- Small scale space enthusiasts can enter planetary exploration via such small payload delivery systems

- Maximum deceleration: 11.5 m/s (3.28 ‘g’)

- Altitude of maximum deceleration: 20.40 km from surface

- Velocity at maximum deceleration: 491.93 m/s

- Maximum dynamic pressure: 880 Pa

- Drag force at maximum deceleration: 180 N

- Altitude of maximum heating: 8.20 km from surface

- Maximum heating rate: 3033 Watt/sqm (lesser than the space capsule recovery experiment heating rate as achieved by ISRO in earth atmosphere)

Gessler

New Member

- Joined

- Jan 10, 2016

- Messages

- 2,312

- Likes

- 11,249

Where is the article/source?IAD stands for Inflatable Aerodynamic Decelerator, otherwise known as Aerodynamic Decelerator Atmospheric-entry Module (ADAM). The system is being designed jointly by VSSC and IIST for deployment off of a Mars orbiter. More about ADAM :

Additional details :

- ADAM is an atmospheric entry module that delivers safely micro/mini probes/payloads to Martian surface, weighing from minimum 5 kg to 15 kg net weight relevant for small scale researchers and explorers.

- Conceptualized as a stretched sphere (tear drop shape during its atmospheric entry) and the rear cone separates out during the parachute deployment transforming the module to a sphere.

- This sphere drops down decelerating, aided with three thrusters to bring down the velocity to near zero value for a safer touchdown.

- Visco-elastic damping materials serves as shock absorbers to prevent impact load transfer to the payload inside.

View attachment 44970

- Outer aeroshell in the shape of a stretched sphere (tear drop shape)

- Multiple layer of Thermal Protection System (TPS)

- Visco-elastic shock absorbing layer

- Decelerator system consisting of parachute and thrusters

- Concept is analogous to advent of mini-satellites when larger spacecrafts of agencies reign the space arena.

- Small scale space enthusiasts can enter planetary exploration via such small payload delivery systems

- Maximum deceleration: 11.5 m/s (3.28 ‘g’)

- Altitude of maximum deceleration: 20.40 km from surface

- Velocity at maximum deceleration: 491.93 m/s

- Maximum dynamic pressure: 880 Pa

- Drag force at maximum deceleration: 180 N

- Altitude of maximum heating: 8.20 km from surface

- Maximum heating rate: 3033 Watt/sqm (lesser than the space capsule recovery experiment heating rate as achieved by ISRO in earth atmosphere)

View attachment 44971

View attachment 44972 View attachment 44973 View attachment 44974

Please post.................

- Joined

- Apr 29, 2015

- Messages

- 18,416

- Likes

- 56,946

Was supposed to fly in mid 2021, now will be delayed due to COVID 19.Any news or information about ISRO's semi Cryo engine....

Karthi

New Member

- Joined

- Jul 15, 2018

- Messages

- 2,214

- Likes

- 17,755

Umbilical tower (UT) of Second Launch Pad (SLP) at SDSC SHAR, Sriharikota is a

70m tall octagonal shape steel tower used for launching of ISRO launch vehicles. As part of the augmentation of launch pad system for requirements of human space flight (Gaganyaan mission), there is a need of structural augmentation/modification of UT systems for crew ingress & egress at launch pad. The structural works like realization of extension platforms by deriving support from the existing columns, crew access arm, locking arrangements will be carried out for crew entry & exit. The structural works will contain the fabrication of hot rolled steel sections at site and machining of components like hinge shaft, bearing retainers/housing etc. Some of the bought out items like bearing, fasteners, rollers etc also will be used during erection of elements/components. The mechanical systems like crew access arm (CAA), lock & unlock mechanism etc. will be interfaced with hydraulic/electric drive system and PLC based control system for remote operation of mechanisms. For emergency escape of crew from launch pad, wire rope basket system will be realized by deriving support from the extension platforms to be realized at EL 46m.

70m tall octagonal shape steel tower used for launching of ISRO launch vehicles. As part of the augmentation of launch pad system for requirements of human space flight (Gaganyaan mission), there is a need of structural augmentation/modification of UT systems for crew ingress & egress at launch pad. The structural works like realization of extension platforms by deriving support from the existing columns, crew access arm, locking arrangements will be carried out for crew entry & exit. The structural works will contain the fabrication of hot rolled steel sections at site and machining of components like hinge shaft, bearing retainers/housing etc. Some of the bought out items like bearing, fasteners, rollers etc also will be used during erection of elements/components. The mechanical systems like crew access arm (CAA), lock & unlock mechanism etc. will be interfaced with hydraulic/electric drive system and PLC based control system for remote operation of mechanisms. For emergency escape of crew from launch pad, wire rope basket system will be realized by deriving support from the extension platforms to be realized at EL 46m.

Karthi

New Member

- Joined

- Jul 15, 2018

- Messages

- 2,214

- Likes

- 17,755

Umbilical tower (UT) of Second Launch Pad (SLP) at SDSC SHAR, Sriharikota is a

70m tall octagonal shape steel tower used for launching of ISRO launch vehicles. As part of the augmentation of launch pad system for requirements of human space flight (Gaganyaan mission), there is a need of structural augmentation/modification of UT systems for crew ingress & egress at launch pad. The structural works like realization of extension platforms by deriving support from the existing columns, crew access arm, locking arrangements will be carried out for crew entry & exit. The structural works will contain the fabrication of hot rolled steel sections at site and machining of components like hinge shaft, bearing retainers/housing etc. Some of the bought out items like bearing, fasteners, rollers etc also will be used during erection of elements/components. The mechanical systems like crew access arm (CAA), lock & unlock mechanism etc. will be interfaced with hydraulic/electric drive system and PLC based control system for remote operation of mechanisms. For emergency escape of crew from launch pad, wire rope basket system will be realized by deriving support from the extension platforms to be realized at EL 46m.

70m tall octagonal shape steel tower used for launching of ISRO launch vehicles. As part of the augmentation of launch pad system for requirements of human space flight (Gaganyaan mission), there is a need of structural augmentation/modification of UT systems for crew ingress & egress at launch pad. The structural works like realization of extension platforms by deriving support from the existing columns, crew access arm, locking arrangements will be carried out for crew entry & exit. The structural works will contain the fabrication of hot rolled steel sections at site and machining of components like hinge shaft, bearing retainers/housing etc. Some of the bought out items like bearing, fasteners, rollers etc also will be used during erection of elements/components. The mechanical systems like crew access arm (CAA), lock & unlock mechanism etc. will be interfaced with hydraulic/electric drive system and PLC based control system for remote operation of mechanisms. For emergency escape of crew from launch pad, wire rope basket system will be realized by deriving support from the extension platforms to be realized at EL 46m.

Karthi

New Member

- Joined

- Jul 15, 2018

- Messages

- 2,214

- Likes

- 17,755

Plan view of 46m extension platform

It is proposed to create extension platforms at EL 42.9m and EL46m by deriving support from the existing UT columns. The 42.9m platform will be supported from 42m platform. The 42.9m platform will be used for crew entry and the 46m platform will be used for erection of hinge system of crew access arm. Further the 46m platform will be used for fixing of pulley system of zip line, lock and unlock system of SCVRP & CAA. The extension platform is structural platform fabricated with steel material as per the given drawing.

The plan view of the 42.9m extension platform and 46m extension platform is shown in the figure 3 and 4 below. The overall dimension of the 46m platform is around 4.25m X 3m while the overall dimension of the 42.9m platform is approximately 10m X 7.5m. The approximate weight is 28t.

Karthi

New Member

- Joined

- Jul 15, 2018

- Messages

- 2,214

- Likes

- 17,755

Crew access arm (CAA) view

The crew access arm is rotating cantilever structure arm connected from hinge being supported on 46m extension platform. The hinge will be rotated through a hydraulic actuator. The CAA is a 12m long cantilever boom having opening of 1.25m width and 2.3m height opening for crew entry. The structure of the boom is made up of MS pipes and the floor is cover with chequired plate. The approximate weight of boom is: 4t

Articles

-

India Strikes Back: Operation Snow Leopard - Part 1

- mist_consecutive

- Replies: 9

-

Aftermath Galwan : Who holds the fort ?

- mist_consecutive

- Replies: 33

-

The Terrible Cost of Presidential Racism(Nixon & Kissinger towards India).

- ezsasa

- Replies: 40

-

Modern BVR Air Combat - Part 2

- mist_consecutive

- Replies: 22

-

Civil & Military Bureaucracy and related discussions

- daya

- Replies: 32