@Lonewolf I got an update for you about SCE-200, this update is from Strategic Frontier Forum

The SCE-200 engine began life with ISRO acquiring the Ukrainian RD-810 semi-cryogenic engine blueprints from the Yuzhnoye Design Bureau in 2005. The design of the engine was the only thing that was acquired. Other vital stuff like the mathematical models, materials used etc. were not brought.

This means ISRO had know how without the know why. So they had to reverse engineer the know why. Along the way ISRO made modifications to the engine design, materials, production methods, fuel etc. thus making the SCE-200 engine a derivative of the RD-810 not an exact replica. Besides the Ukrainians themselves have never built the RD-810, so you can't really say its a proven design.

The engine was originally designed to use RP-1 as the fuel. ISRO wanted to use their own Kerosene derivative called the Isrosene. The original design assumed most of the components of the rocket will be made conventionally by using processes like investment casting, ISRO began 3D printing the components. Reverse engineering the know how and making changes to the original design took around a decade.

View attachment 89409

Low Pressure Oxidiser Turbo(LPOT) pump.

View attachment 89411

Some breakthroughs made in metallurgy

View attachment 89413

Single element thrust chamber hot test

View attachment 89429

Injector design experiments

Component level testing began in around 2015. Small scale tests were conducted to fix the propellant to oxidiser ratio for Isrosene. Igniters were also designed and tested. New materials were being experimented with. Components level testing continued for another 2 years, in 2017 ISRO signed an agreement with the Yuzhmash production facility for hot testing full sized engine components. The entire engine was planned to be tested in India.

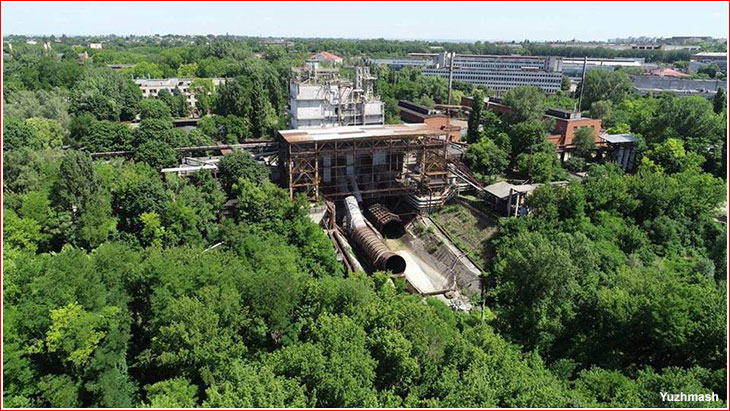

View attachment 89439

Aerial view of the propulsion testing facility at the Yuzhmash plant in Dnipro, Ukraine.

ISRO Propulsion Complex (IPRC) in Mahendragiri had set up a Semi-cryogenic Cold Flow Test facility (SCFT) for the development, qualification and acceptance testing of semi-cryogenic engine subsystems. this is where most sub-systems were tested till date. IPRC were also sanctioned by ISRO to build a new test stand for hot fire testing of the full sized engine. A new test stand is needed as the current test stand was simply inadequate for handling the ~2MN thrust output of the SCE-200. But that project got delayed due to unknown reasons. As of 2021 the new test stand is yet to be completed.

View attachment 89438

Satellite image of the under construction new test stand from 2018.

ISRO had sent Indian made engine components to Ukraine in 2018-2019 period. The component tests were supposed to end by 2019. After the tests end the components would be shipped back to India where they would be assembled to build a full sized engine. No news was heard of the SCE-200 component tests in the Indian, Ukrainian or any other media. At least nothing on the English language media. If something was published in the Ukrainian/Russian language media then I have missed it.

And now comes the hypothetical part:

In November 2020, a video was put out on Youtube about the Yuzhmash engine plant :

An Ukrainian member posted this on NASASpaceflight forum suggesting that a new engine shown in that video was the SCE-200 engine. The narrator in the video remarks the engine was a unique design & produces tremendous thrust. Then the narrator adds that the engine belongs to a foreign nation adding they will not disclose which nation it is.

Here are some screenshots of the engine :

View attachment 89437

View attachment 89435

View attachment 89434

This Engine is supposedly SCE-200

I initially dismissed this as some other engine of some other country. But now I think it may be the SCE-200 after all. In a recent presentation Dr. S. Somanath showed slides that put the estimated timeline of the development of a SC400 rocket stage based on the SCE-200 engines to be a just 2 years away. That would naturally mean the engine is very close to being ready.

View attachment 89430

After seeing the above slide, I wonder whether ISRO is planning Manned Gaganyaan flight using the HLV, because the timelines mentioned for Human-rated HLV (2023) match with that of 1st Manned Gaganyaan flight.

Last year there was a tender for making trailers for the SC120 stage to be used in the GSLV Mk-3 augmentation project. If they are calling tenders for trailers for the SC120, surely design of the stage has been finalised. There is no way of finalising a rocket stage design without testing the engine prototypes. Looking at it from that POV it does seem likely that the engine shown above is indeed the SCE-200. Maybe the agreement between ISRO and Yuzhmash stretches beyond hot testing engine components. Maybe they would assemble the engine and conduct hot tests on it too.

When ISRO acquired the RD-810 blueprints from the Yuzhnoye Design Bureau they offered to help design an entire launch rocket based on that engine. Of course from the RD-810 to the SCE-200 the engine design has changed quite a bit. Wonder if that offer still stands.

YUP

https://www.russianspaceweb.com/rd810.html

Ukraine to test components of a powerful Indian rocket engine

The Yuzhmash production plant in Ukraine prepares to begin a series of firings testing critical parts of a large rocket engine intended for India's next-generation heavy launcher. Although it was built entirely in India, the prospective engine was originally designed in Ukraine under designation RD-810.

Previous chapter:

Mayak launcher

A version of the RD-810 engine circa 2013 designed to gimble around one axis.

The RD-810 engine at a glance:

| Oxidizer | Liquid oxygen |

| Fuel | Kerosene |

| Thrust at sea level | 194.2 tons |

| Thrust in vacuum | 211.3 tons |

| Specific impulse at sea level | 303.6 seconds |

| Specific impulse in vacuum | 330.3 seconds |

| Engine mass | 2,350*/2,500** kilograms |

| Number of burns in flight | 1 |

| Propellant component ratio | 2.65 |

| Combustion chamber pressure | 192.7 kilograms per square centimeter |

| Gimbal angle | in one or two axis |

| Burn time | ~140 seconds |

| Length | 4,015 millimeters |

| Nozzle diameter | 1,450 millimeters |

*With one-axis gimbal mechanism; ** for two-axis gimbal mechanism

From the publisher:Pace of our development depends primarily on the level of support from our readers!

|

Developing RD-810

The RD-810 was developed at KB Yuzhnoe in today's city of Dnipro, Ukraine, as an equivalent of the Russian

RD-191 engine, but using a more conservative engineering approach. Like the RD-191, this one-chamber engine with a thrust of around 200 tons, was intended for the first stage of a new-generation space launcher, however it was designed to operate at a lower, and thus safer, internal pressure than that accepted in its Russian counterpart.

The propulsion division at KB Yuzhnoe was able to take on the project of such a scale and complexity thanks to its most recent experience with the engines for the

second stage of the

Zenit rocket, including the RD-120 and RD-8.

The RD-810 belongs to the so-called staged combustion cycle engines, which first ignite their propellant mix inside a special gas generator (also known as pre-burner). The resulting hot gas is used to drive the engine's turbine and then it is directed into the main combustion chamber.

The RD-810 was designed for a single firing during the operation of a typical first stage, starting on the ground and lasting slightly more than two minutes. The engine could operate in two modes: burning at full thrust for 135 seconds and then switching to a lower thrust for the final six seconds before the separation of the first stage. (

809)

In the course of its development, several versions of the RD-810 were designed, with the main difference being its gimbal mechanism with either one- or two-axis steering.

Foreign roles for RD-810

Over the years, various roles were proposed for RD-810, including replacing the Russian RD-171 on the Ukrainian-built Zenit rocket and propelling Ukraine's new-generation

Mayak launcher. A four-engine cluster, dubbed RD-810M, was designed to fit into the aft section of a potential space booster with a diameter 3.9 meters, matching the caliber of the Zenit rocket. Each RD-810 was expected to gimbal up to six degrees around one axis, allowing the four-engine cluster to fully steer the rocket.

Because none of the indigenous programs could be adequately funded, Ukraine sought to bring the RD-810 design to the international market. Along with several other Ukrainian designs, the RD-810 was proposed for the American super-heavy rocket developed under the Space Launch System, SLS, program. However, despite qualifying RD-810 as in high degree of readiness, American space officials did not seriously consider Ukrainian engines for the SLS project.

Indian version

In 2005, Ukraine agreed to provide India with designs for the RD-810 engine and, on Nov. 20, 2006, the Indian Space Research Organization, ISRO, awarded a contract to KB Yuzhnoe for a project code-named Jasmine, which officially started the development of the RD-810. In India, the RD-810-based engine was dubbed SCE-200, which stood for "semi-cryogenic," indicating the use of kerosene fuel, which can be stored at regular temperatures, and liquid oxygen, which requires cryogenic conditions to stay in liquid form. The "200" in the designation denoted its thrust of 200 tons.

ISRO planned to install the SCE-200 engine on the modified core stage of the GSLV Mark 3 rocket replacing the older propulsion system. It would boost the payload capacity of the rocket to the geostationary transfer orbit from four to six tons. Later, four similar engines could propel a new-generation rocket, which could deliver up to 10 tons to the same orbit without the help of strap-on boosters.

In addition to assisting with the design of the engine, KB Yuzhnoe also advised ISRO on the development of the prospective launch vehicle itself.

RD-810 for Antares

In September 2013, KB Yuzhnoe proposed the RD-810 engine for the US

Antares rocket developed at Orbital ATK. The company promised to begin deliveries of the engine in 5.5 years at a price tug of $500 million. However, Orbital chose the Russian

RD-181 engine for the project.

As of 2014, KB Yuzhnoe had produced the full set of design documentation required for the production and testing of the RD-810 engine. (

809) According to industry sources, India then re-issued the blueprints for the engine according to its own standards and, possibly, introduced some modifications.

In the meantime, KB Yuzhnoe decided to stop further development of the RD-810 engine inside Ukraine, focusing instead its limited resources on the more powerful RD-815 design, which could potentially be promising on the US market.

Testing RD-810

Aerial view of the propulsion testing facility at the Yuzhmash plant in Dnipro, Ukraine.

In 2017, Indian specialists returned to Ukraine to test fire the actual hardware, which had been built in India within the Jasmine project. According to industry sources, the Ukrainian Yuzhmash factory was contracted to test, not the entire engine, but its critical components, including its gas generator and a turbopump, which had all been manufactured in India. If the firings, apparently planned to be completed by 2019, validated the quality of the Indian manufacturing methods, the fully assembled engine, including the combustion chamber and the nozzle, would be tested at the yet-to-be completed bench facility at Mahendragiri, India.

(To be continued)