A 70-member team consisting of scientists and technical officers from the Mysuru-based Defence Food Research Laboratory (DFRL) is locked on to dish out tasty and nutritious-meals-cum-solutions for India’s big ticket Human Space Programme — Gaganyaan. The ready-to-eat (RTE) space food is expected by March 2021. It will undergo trials during the two unmanned missions being planned by Indian Space Research Organisation (ISRO) ahead of the final Gaganyaan manned flight. Sources in the Defence Research and Development Organisation (DRDO) told Onmanorama the scientists developing space food are mostly in the age group of 40-45 years, with expertise in food technology, microbiology and biotechnology. Among the technologies that are being developed by DFRL for Gaganyaan mission include waste disposal system (leftover food), liquid dispensing system, food rehydrating system and food heater, to name a few. Currently, the plan is to make space food sufficient for seven days. The exact days of Gaganyaan mission and the number of astronauts likely on board are not known yet. DRDO sources said that DFRL, headed by Dr Anil Dutt Semwal, began the work for Gaganyaan mission in September 2019 after signing a memorandum of understanding (MoU) with ISRO. “The lab has been constantly getting inputs from ISRO on the standards to be maintained while developing space food. ISRO on its part has been consulting India’s first and only astronaut Wg Cdr Rakesh Sharma (Retd) for his guidance on several aspects of the manned flight,” a DRDO official said. Interestingly, DFRL initially got the exposure to develop space food in 1984 during Rakesh Sharma’s mission. It had then provided RTE mango bar and freeze dried (ready to reconstitute) pineapple/ mango juice powders. Suitable for space missions, these RTE products always stayed near to fresh, light-weight and would rehydrate instantly.

Challenges Galore

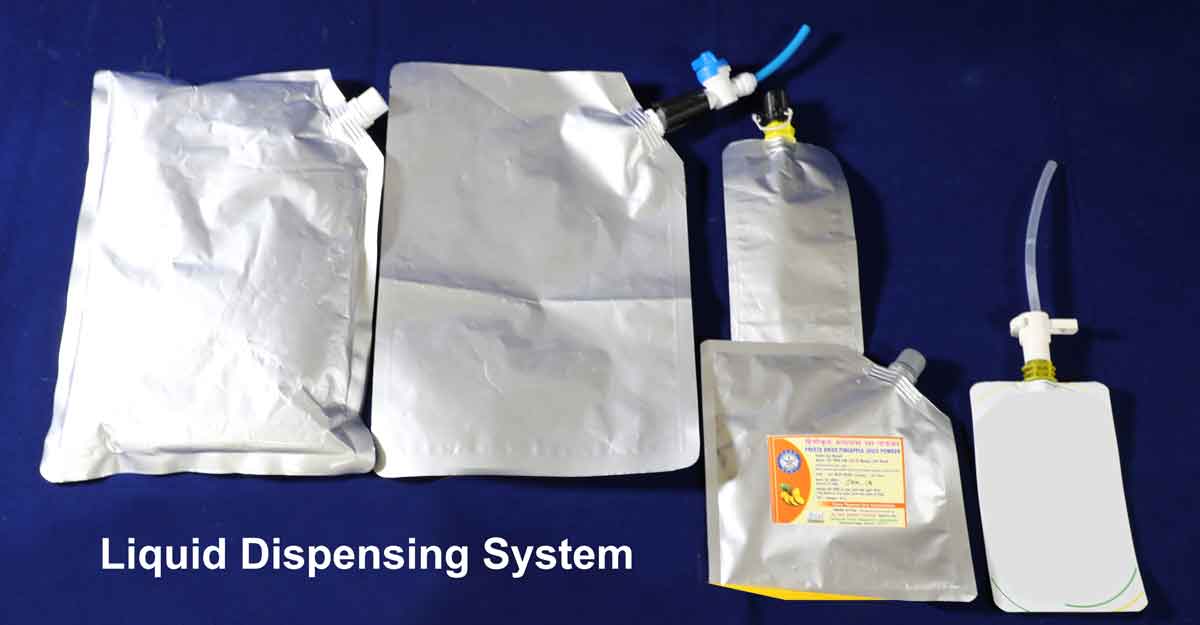

There are several challenges in developing space food meeting very stringent quality standards. The scientists will have to ensure nutritional adequacy that meets macro and micronutrient requirements while developing food meant for space missions. “The task becomes tougher while meeting quality criteria such as light weight, low volume, quick preparation, easy to consume, low fragmentation, high acceptability, wholesomeness, stability, variety, gastro-intestinal compatibility, minimum residue and appropriate packaging,” says a DRDO official overseeing DFRL’s missions. The design of suitable liquid delivery systems, reconstitution and rehydration of systems, food heater and food waste restraining bags are all tasks embedded with greater challenges. “The scientists have been instructed to ensure space worthiness of these products while constantly keeping in mind the physiological changes in astronauts under microgravity conditions,” confirms an official, who is part of this national mission. While refusing to share any information about the number of products that have been already developed and ground-tested for Gaganyaan mission, the official said: “Development and testing is an integral part of any mission and DFRL will meet the schedule of Gaganyaan mission. The details about the required ground test cannot be revealed at present as it is a part of development and is protected by IP rights.” On the parameters that go into making of space food menu, he said DFRL pooled in all its expertise in the area of food technology. “There are several parameters that fall into the science and technology of developing space food. Parameters like calorie, nutrition, easy and quick preparation and stability are important criteria to decide the food,” says an official. The space food is being processed to have long shelf life and stability. Also, the processing parameters were standardized to achieve microbiological targets specified for each category of food.

Quality Key

The space food will have to finally pass a chain of quality processes. The tests are specified in the quality control plan, which is well documented. This includes several tests for the food and packaging material being used. “Non-inflammability of the packaging material is an important aspect. Even the food warmer/heater is also designed to heat the contents of the pouches,” says an official. Quality tests will ensure that the menu is adequate to meet the calorific requirements, macro (protein, fat and carbohydrates) and micronutrients (minerals, vitamins and fatty acids). To evaluate the safety and stability of the products, standard microbiological chemical parameters were tested internally and also were subjected to third party evaluation by National Accreditation Board for Testing and Calibration Laboratories-accredited institutions.

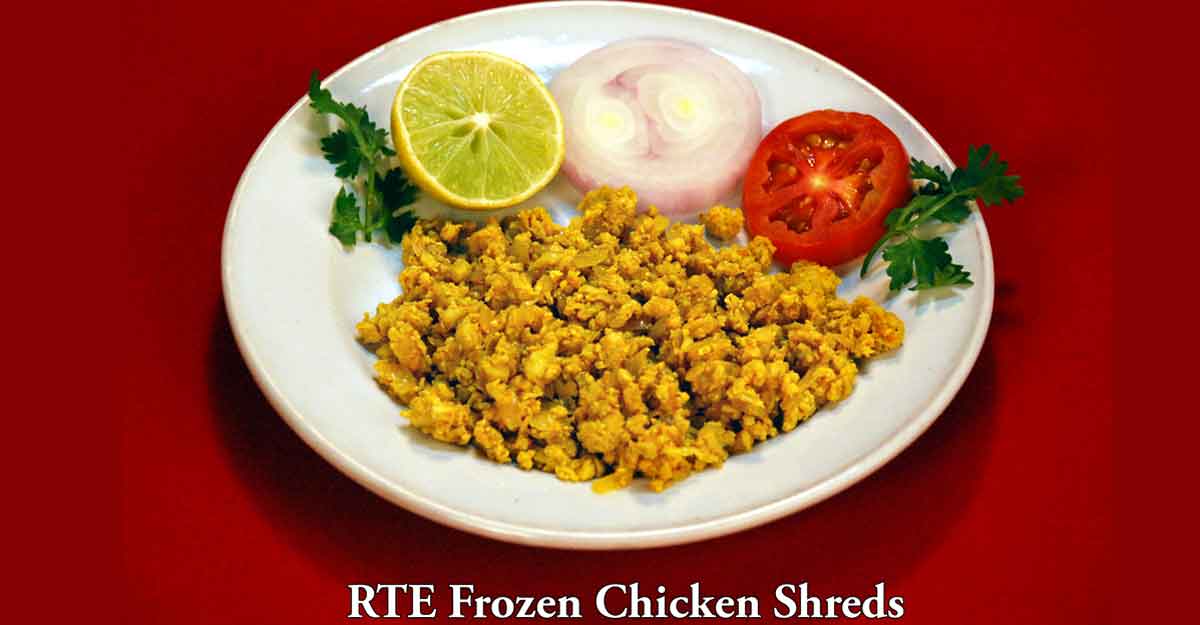

The Menu

For Gagaanyaan mission, sources say DFRL products have been screened for its space worthiness by subjecting them to detailed macro\micro nutrient analysis, sensory evaluation, microbiological safety and acceptability as per NASA standards. A detailed menu has been formulated taking into account the calorie requirements of the astronauts. The exhaustive menu based on retort processing technology include: vegetable pulav, vegetable biryani, sooji halwa, shahi paneer, dal makhani, chicken biryani, chicken katti rolls, katti rolls (egg), katti rolls (paneer, sweet corn), potato-stuffed parotha, dal chawal, kadi chawal, rajma chawal, sambar chawal, preserved chapaties along with oral rehydration solution (ORS) and saline water. On the freeze dried segment, the astronauts can choose from pineapple juice powder, carrot/cucumber, chicken shreds. Instant food like idli sambar, khichidi, moong dal halwa, coconut chutney, jiffy upma are also on the menu. The snack section has fruit and nut bar, Omega-3 rich bar, dates bar, chocolate bar, mango bar, combination tech processed dry fruits (salted almond, cashew and pumpkin seeds), beans in sauce, tomato sauce, pickle (mango/lemon). Beverages like mango nectar, coffee and tea will also likely hit the space. “The packaging material and its qualification and specification requirements have been formulated and its design, volume and packing size have been standardized. The water dispensing design has been set for potable water in pouches to meet micro gravity conditions,” says an official. The liquid delivery system has been designed with greater care with the entire assembly being made leak proof. “This will prevent the liquid from creeping out when not being consumed. The scientists have designed an assembly using a valve type opening and closing system,” says the official. A food warmer has been designed exclusively for space food, giving a core temperature of 60-70°C within an average time of 8 to 10 minutes. A prototype of an in-pouch rehydration system also has been designed for instant food items. Plans are afoot for proper biological solid waste management inside the crew module. DFRL scientists have earlier made similar food for Indian Air Force (IAF) pilots in the forms of preflight meals like freeze dried chicken, porridge mix and alertness-inducing coffee paste. Low glycemic index (GI) chicken khakhra is a product developed as a convenient snack with a lasting shelf-life. All these products have already been sent for trials with the IAF. Interestingly, a recent NASA feature says that the crewmembers at the International Space Station (ISS) today have the luxury of choosing from 200 different items from their standard menu, including some personal choices. “We will get there one day as we have the expertise to deliver space food. NASA and ISS have set benchmarks with several manned missions and Gaganyaan will set the ball rolling for us,” says an official. DFRL is banking on its high success rate of delivering quality RTE food to Indian armed forces over the years. From developing terrain specific food for high altitudes, deserts to energy dense items for light intensity conflict and combat situations, the scientists are confident to take up the challenges thrown at them by the Gaganyaan mission.