LED Industry: China leaps as India sleeps - Moneylife Personal Finance site and magazine

Out of India's total use of electrical power, over 60% in domestic and commercial area is for lighting. As India continues to sleep, China is today lighting up many Indian homes and commercial premises through Indian LED trading businesses

While the Indian government is busy with non-issues, globally the light emitting diode or LED industry is rapidly growing and China leads the pack claiming huge share in global production. Having started with downstream end of the LED industry that handles packaging, testing and application, it is now fast gaining grounds in the middle stream industry like chip processing and also in the upstream of the industry that includes producing mono-crystalline LED chips and epitaxial wafers. In India, development of this industry is left to small players in the private sector with little initiative from the government. We seem to be just ignoring the future.

Why is LED important for India?

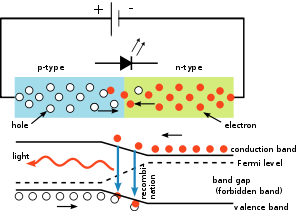

LED or Light Emitting Diode turns electrical energy into luminous energy and does it so efficiently that it gives nine times the light than the filament bulbs we use. Compared to CFL lights its light output is three times! LED can emit visible light in various colours such as super bright white, yellow, green, blue, etc, as well as invisible light, such as infrared and ultraviolet light. In other words, for the same light output, it consumes just one-ninth the power compared with a small incandescent bulb and one-third of a CFL lamp, LED light sources also have a very long life and possess far higher reliability. That means today's 11W LED light will give same light output in Lumen as 100W conventional filament bulb. See the table below for the comparison and merits.

Thus LEDs will help us reduce our power demand tremendously. Our power needs will sharply reduce since 60% of the electrical energy used in India is for lighting. This will eliminate the need for us to turn to dangerous and expensive nuclear energy and enrich the western multinationals like those in France or the US. LED prices are continuously dropping. As the volume goes up they will drop further. It is predicted that in the next 10 years, one might see LED prices as low as or cheaper than the conventional light sources. Unfortunately the Indian government and industry has so far ignored to make it our priority.

LED lighting business in India has grown 50% each year since 2008. It was about Rs850 crore in 2011 and is likely to reach Rs1200 crore in 2012 according to the LED companies in India. Most of these products are imported from China!

China LED Industry gallops to Rs 25,000 crore in 2011

Taking full advantage of the government support, China's LED industry has logged over Rs25,000 crore in sales by offering a wide range of innovative products. This is 23% more than in 2010. (NYSE: IHS). They are poised to grow almost double to Rs46,000 crore by 2015. India could have taken a big share in this had we taken the initiative in 2007 when the author send his first alert to the government.

The LED market covers LED bulbs, LED displays, traffic signals, LED for automotive use, LCD backlighting, handset key pads, digital still camera flashlights, decorative lighting, street lighting and general illumination. A new demand driver for LEDs in the medium to long-term will be the general lighting market. Given the global trend to reduce carbon emissions, China's demand in the general lighting segment will be strong for LEDs, which offer low-power consumption and are environmentally safe. The Chinese, however, are not happy since most of LED wafers are to be imported which indeed have the largest value addition. China trails due to the lack of technological and research and development (R&D) capabilities but its government is liberally financing local R&D as well as encouraging foreigners to set up plants in China. China's LED players enjoy ample funding from the government. It subsidises at least 70% of the purchase price for metal organic chemical vapour deposition equipment employed in LED manufacturing. Furthermore, tax and utility payment benefits are offered to encourage investments in the domestic LED industry, proving to be an additional boon for local players.

In 2012, the Chinese LED industry has formed the basically complete industrial chains, covering the LED inside, epitaxial wafer, chip package and application. At present, China has over 1,100 LED enterprises specializing in the downstream packaging and application. But the development of the epitaxial wafer and chip in China is comparatively backward. There are only about 10 enterprises engaged in the production of the epitaxial wafer for LED, as well as few chip manufacturers.

There is yet another important reason why the Chinese are keen to go upstream. In the industrial chain of light emitting diode, epitaxial wafer and chip account for about 70% of profits and the packaging accounts for just 10% to 20% of profits, with 10% to 20% held by application field.

Indian Scene:

In spite of the availability of cheaper technical manpower than China, India has little manufacturing of LEDs; none at the mono-crystalline chip level, none at packaging chips into sources for lighting in various forms and very small application level, mostly from kits from China. India's LED product sources are just traders of (mostly) Chinese end products.

The Government of India is too busy with politics of one-up-man-ship that it is not even thinking of any plan. The investor community has sheep-herd mentality and that's why we see so much unwise investment in downstream levels of PV Solar. There would soon be bankruptcies in that sector. Even the PV cell manufacturers in India are today trading products from China and Taiwan. China too will see even more serious crash.

No one seems to look at basics. Out of India's total use of electrical power, over 60% in domestic and commercial area is for lighting. LEDs are basically just like sand so its prices will continue to fall as the high initial investments get depreciated and competition drives down the prices. Notice that there is 70% value addition today at the chip level in LEDs.

As India continues to sleep, China is today lighting up many Indian homes and commercial premises through Indian trading businesses. Well-known Indian and foreign brands sold in India get their branded Indian products from China. What a pity Dr Manmohan Singh!

PS Deodhar is founder and former chairman of the Aplab Group of companies. He is also the former chairman of the Electronics Commission of the Government of India and was an advisor to late Prime Minister Rajiv Gandhi on electronics. He also was the chairman of the Broadcast Council in 1992-93 that set in motion the privatisation of the electronic media with metro channels

LED lights i use in ma car ma bike ma kitchen, hell, even in ma toilet Yo ! LED lights saves teh day

LED lights i use in ma car ma bike ma kitchen, hell, even in ma toilet Yo ! LED lights saves teh day