Pranav Mahamuni said he has a vision for the electronics industry of the country, of bringing this untapped advanced technology to and helping reshape the electronics industry of the country.

www.ibtimes.co.in

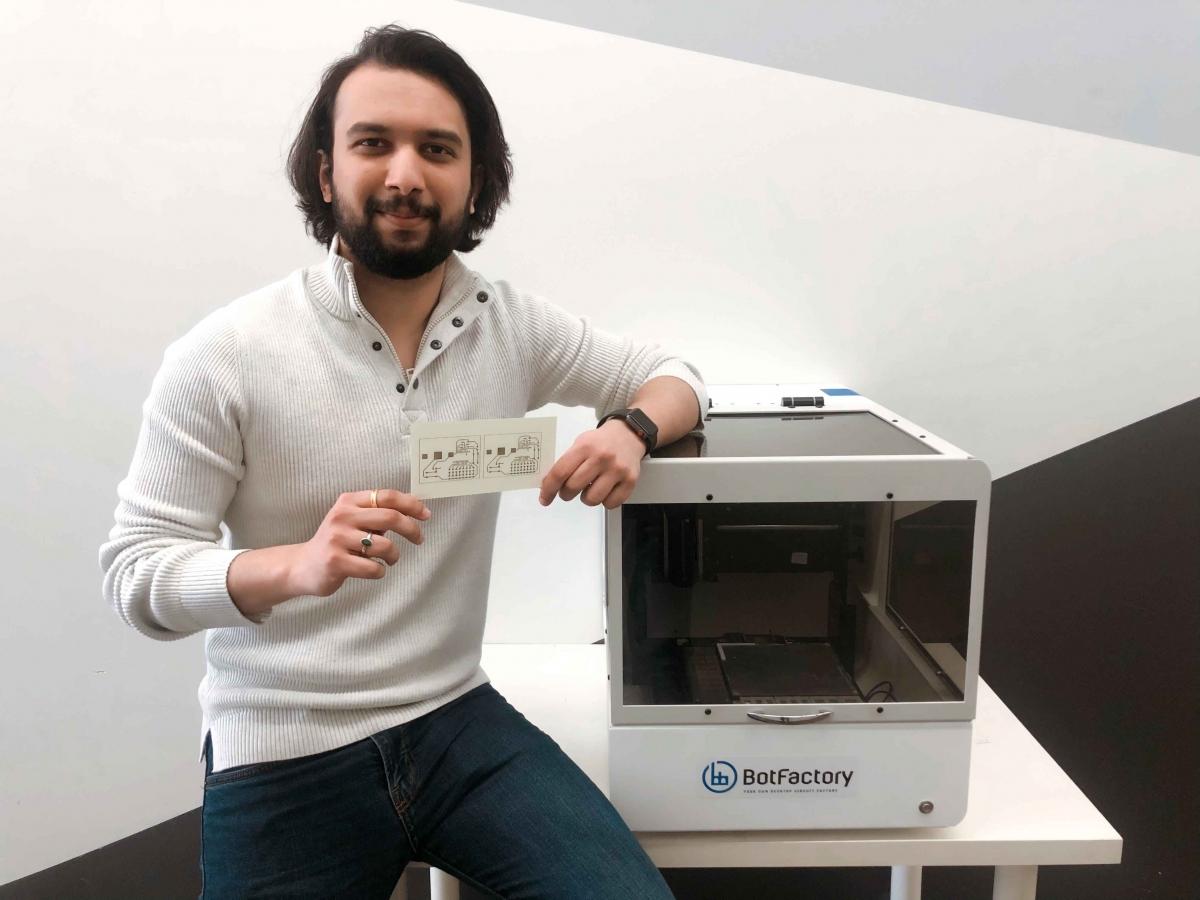

Meet Pranav Mahamuni, who is trying to improve PCB manufacturing in India

Innovation is a word that has caught a lot of attention amongst the youth of our developing country, but very few do implement the very definition of this word. To bring about a massive change in the very existing scheme of things takes an extraordinary grit and an out-of-box perspective. Meet Pranav Mahamuni, a Lead Mechanical Engineer working at New York-based startup BotFactory Inc. who is responsible for pioneering revolutionary work in the electronic circuit board industry.

He began his journey in Mechanical Engineering in 2011 from the University of Pune where he was fascinated and involved with Research in Product Design. During this time, he realized the immensity of crafting efficiency as an important factor for new products to work. He had the necessary intent and idea about this industry but knowledge and valuable training were lacking. With this, he decided to get a Masters' Degree from Stony Brook University where he was even awarded several honors for his work. He has always been inclined towards working at a startup than at a major corporation, the reason behind this, he jokingly says – "When you work for a major company you are only working on a piece of a puzzle, but when you work for a startup you are solving the entire puzzle, I am interested in the entire puzzle, not a single piece."

He says "After my master's education in the USA, I joined a new york-based startup BotFactoy as a Mechanical Engineer and was part of a team that developed the first 3D PCB printer.

BotFactory leveraged a fast-rising 3D printing technology that throws out a very impressive outcome because PCBs that took weeks for development and involved expensive processes were suddenly able to be manufactured within a very short span and were super inexpensive. This extraordinary technology can enable and empower the Indian electronics industry in a manner not seen before and I'm excited about the possibility that this highly advanced & revolutionary technology will bring to my native country - India."

India meets its staggering 70% demand for electronic components through imports, mainly for the construction of consumer electronic and medical products. Reducing this growing import reliance on electronic components has been one of the hardest challenges faced by the Indian government in the last few years. There are few major factors that are affecting India's PCB industry growth such as lack of access to new technology and state-of-the-art manufacturing facilities, high capex requirements, logistic inefficiencies resulting in longer turnaround frames. "Despite these drawbacks, sustained growth in India's PCB industry can be achieved if it adapts to emerging advanced technologies such as 3D PCB printing offered by BotFactory, Inc.," he adds

"I have a vision for the electronics industry of the country, of bringing this untapped advanced technology to and helping reshape the electronics industry of the country in its entirety," he said.