Some insights on how to make your own assault rifle the right way!

THE CARACAL CAR816: THE NEW DESERT ASSAULT RIFLE

2 September, 2016 · by

admin · in

Features,

Reviews,

Search By Issue,

V8N4,

Volume 8

ABOVE: The Caracal CAR816 in the hands of a UAE soldier. This rifle is the basic assault rifle with a 14.5 inch cold hammer forged barrel. This is destined to be a basic infantry rifle in the Gulf region.

Small Arms Defense Journal first visited the Caracal factory in Abu Dhabi in February, 2011 when the new production of the Models C and F were coming off the newly constructed production lines. That article was in SADJ V3 No 3 and is online. Here, five years later, SADJ writer Chris Bartocci returns to see the amazing growth of not only the factory, but the scope of Caracal’s ambition and production.

The Gulf region has always been dependent on foreign nations to provide their security forces with small arms and ammunition. The region exports oil, mining products, and some agricultural items, but that is really about it. That can be a dangerous situation, depending on foreign nations for all of your war materials. It’s especially difficult when diplomatic relationships are so fragile in the region. One day the US State Department approves the license to send small arms, spare parts and ammunition but the next time the license is applied they may deny it if there are any political issues between the two nations. The United Arab Emirates has decided this is unacceptable and has taken steps to make the UAE self sustainable by creating small arms and small arms ammunition manufacturing right in Abu Dhabi. This is a major challenge for many reasons. The Middle East is not populated with a large work force trained in modern engineering and manufacturing. American firearms manufacturers are generally surrounded by machine shops and “job shops” that specialize in various manufacturing process that are used in the manufacturing of small arms. This would include shops that mold polymer components, heat treat, perform chroming, hammer forging, casting and forging aluminum receivers. The Middle East, these do exist but are quite limited. To make the same firearm there you must have a manufacturing facility that can do all these processes in house. That is just what happened with a relatively new company, Caracal. The company first produced two pistols; the 9x19mm models C&F. This was well suited for them to build up their manufacturing capability to produce complete firearms in-house. They have rows of modern CNC machines, modern lathes and deep hole drilling for barrels, hammer forge for barrel production, heat treating, anodizing, polishing, cryo stress relief, MIM and other capabilities.

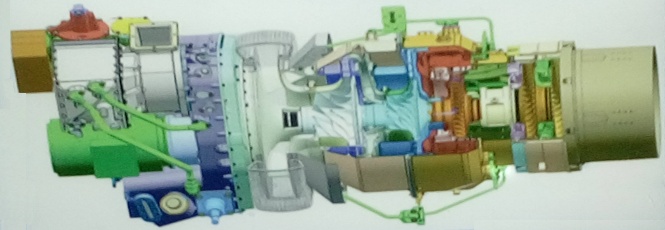

The first Gulf region built assault rifle, the short stroke piston operated CAR816 manufactured in Abu Dhabi, UAE by Caracal. Just like the M4, the rifle will accept any accessory from optics, bayonet, bipod or anything else which may be required.

Now, the company is set out on their next goal, to develop an assault rifle they could sell not only in the UAE but to all the Gulf nations. This would surely put Caracal in a position where if they made as good if not a better assault rifle than their American and European competition, these nations would prefer to buy from a GCC ally where they eliminate the higher costs, logistical issues and eventual political issues that can interrupt the flow of necessary military gear into the countries. In all reality, they might prefer to equip their forces with a home grown product rather than one from abroad.

Caracal set out to design this rifle for their part of the world. They needed to have a first rate engineering and manufacturing staff. They recruited engineers and manufacturing experts from countries such as the US, Germany, Russia and India to name a few. The design leads would come from two of the most well known companies in the industry, Heckler & Koch and Sig Sauer. Robert Hirt was with Heckler & Koch through several programs, most notably the HK416 as well as with SIG Sauer as the VP of Special Weapons Group/engineering/Defense Systems and is the inventor of the 516/517, MPX and MCX programs. Robert is now the Chief Operating Officer of Caracal. Chris Sirois was an engineer with SIG Sauer where he worked on the SIG 516, 517 and the MCX programs. Chris is now the head of research and development at Caracal which include the Design Group, Prototype Shop and Special Weapons Development. The engineers Caracal hired just happened to be the ones intimately involved with the HK416 and the Sig MCX rifles. The CEO of Caracal, Hamad Salem Al Ameri, is not your typical CEO or businessman. He is an active duty UAE Army Special Forces officer who was commissioned in the Royal Military Academy in Sandhurst, UK. Being an end user, he presented the challenge to both engineers. He said to each if they had it to do all over again on each weapon system, what would you do differently to make the guns even better? They both said they had some ideas. Then he set them free to build “that rifle” which resulted in the Caracal CAR816. This rifle is not another black rifle copy. This was designed from the ground up. Particular emphasis was put on the performance of the rifle in the environment at hand. The desert, with the most unforgiving sand or better said powder that is the nemesis of anything with moving parts. This is the environment these weapons are specifically designed to function in.

The aspiration of Caracal is to have a majority of weapon production in house and Caracal is working diligently to achieve this. At present some major components are brought in from high end suppliers but it is clear that the Caracal goal is ultimately to produce a 100% indigenous rifle. By importing components from the US, the ITAR restrictions make sales of the rifle outside the UAE very difficult. With the rifle being made 100% in the UAE, they are free to sell throughout the world with no issues.

The CAR816 is a selective-fire (SAFE, SEMI and AUTO) 5.56x45mm gas-operated via short stroke piston assault rifle. The standard barrel length is 14.5 inches. The barrel also has a bayonet lug. The rifle is equipped with a Caracal made free float handguard system with quad Mil-Std-1913 rails. They cyclic rate is between 750-950 rounds per minute. The overall length with the stock extended is 34.6 inches and with the stock collapsed is 31.37 inches. The weight without a magazine is 7.71 pounds.

The Caracal Personal Defense Weapon with a 7.5 inch barrel. The product lineup of Caracal CAR816 rifles is available in 7.5, 10.5, 14.5 and 16 inch barrels.

Starting at the rear of the rifle, the receiver extension permits 6 positions for the stock. The Magpul STR or CTR stocks are found on the rifles this author has seen. According to Caracal, the stock will be based on the customer request. This too will eventually be a Caracal design in the not so distant future. The buffer differs from the legacy models as well. Unlike the norm, Caracal does not use sliding steel and tungsten weights in the buffer; they use tungsten powder. Current rifles will be found with a standard A2-type pistol grip. This is being replaced now with a Caracal designed pistol grip which resembles a Magpul MOE grip. The texture is different and there is a compartment inside the grip. On the receiver extension endplate is an attachment point for a HK-style hook sling. By nature of the design the attachment point is ambidextrous. The lower receiver is a Caracal design with additional features. The magazine well is flared well for inserting a magazine in low to no light conditions. There are gripping grooves on the front of the magazine well to assist in adverse conditions. Rifles used in this environment can have an ambient temperature well exceeding 100°F before a shot is fired. Once a few magazines run through the rifle the handguard may become uncomfortable to hold. Several of the prototype rifles seen at the factory have Manta rail covers. This is certainly a way to deal with a hot handguard. Caracal has not yet settled on one particular rail protector.

The selector is standard on the left side. Caracal will provide an ambidextrous selector if requested. The bolt catch and magazine catch are standard also but again upon request of the customer will make this ambidextrous as well. Providing a standard ambidextrous rifle is more costly than a standard rifle. It is better for Caracal to offer a standard model and have the flexibility to provide ambidextrous features upon request. The trigger is a standard selective-fire trigger. Caracal will soon be offering a semi-auto only trigger group. The trigger weight is specified between 7.5 and 11.5 pounds. The lower receiver will accept any Mil-Spec upper receiver.

The upper receiver of the CAR816 looks standard but there is a modification to the face of the receiver above the barrel nut extension. It is machined to allow the sleeve for the operating rod. The upper receiver has both a forward bolt assist as well as a fired cartridge case deflector. There is a standard ejection port dust cover which is essential for survival in the sandy Middle East environment. The charging handle shown on the prototype rifles to SADJ is a Vltor ambidextrous charging handle. Production guns will have a Caracal made standard charging handle unless the ambidextrous is requested. The Vltor charging handle is certainly an upgrade and is useful by right-hand shooters as well.

The CAR816 has a three position gas regulator. The three is a little sticky, a projectile tip may be used to rotate it.

positions are normal conditions, adverse conditions and suppressed fire. The regulator is adjusted by depressing a lock and rotating the regulator. If it The barrel itself is manufactured by Caracal in-house. The barrel is cold hammer forged and QPQ finished. Caracal feels this is a much better option than chrome plating. The standard barrel is 14.5-inches and it has a 1 turn in 7-inch right hand twist with 6 lands and grooves. Caracal also provides a 7.5-inch PDW variation as well as a 10.5 and 16 inch barrel. The chamber is modified so the rifle is over-the-beach capable. This is an important feature in the Gulf region for operators working in maritime conditions. This is one area where the American M4 has always fallen short. This has to do with the construction of the chamber and other key areas. However, this is not a flaw in the M4 carbine. It is a manufacturing issue. There are several direct gas impingement rifles that are over-the-beach compatible. Colt had two rifles which they submitted during the SCAR program. In fact, Caracal manufactures the Caracal CAR814 which is a direct gas rifle which is also over-thebeach compatible. The barrel has a standard A2-type compensator but with standard ½-28 UNEF threads, the customer can put any muzzle device they choose.

The free-floating handguard is also designed and manufactured by Caracal. It has quad Mil-Std-1913 rails. The top rail of the handguard is 7.22-inches with an overall top rail length of 13.3-inches. The two side rails provide 9.2-inches of rail and the bottom rail provides 8.7-inches of rail. There are four quick detachment sling mounting points. They are on the front and rear of the side rails on both sides. The handguard is manufactured from 6064 T6 aluminum and hard coat anodized black.

The gas system looks rather simple. The gas regulator has three positions. The first is normal conditions. The second is for abnormal conditions. This includes underpowered ammo or if the rifle is filthy from excessive operation without maintenance. The third setting is for suppressed fire. This reduces gas intake so the cycle rate will not significantly increase due to suppressor use. This is important for the longevity of the rifle components. The regulator is housed in the gas block. The regulator positions are moved by depressing a spring loaded plunger and rotating the regulator. If it is sticky, a projectile can be inserted into the tip of the regulator to give additional leverage. The piston located on the end of the operating rod has two gas rings. The piston, operating rod and operating rod spring are a single assembly that is not disassembled during routine maintenance.

The bolt carrier is also unique to this rifle. The carrier is one piece and machined in-house at Caracal. The back has several ribs cut which assist in water and extremely dirty conditions. Due to the fact that this is operated by a short stroke piston there are “ski’s” located on the bottom of the rear of the carrier to limit the effects of carrier tilt. There has been a significant amount of metal removed from the overall bolt carrier. The bolt is

pretty much standard.

The magazines used by Caracal are standard aluminum GI-type magazines. However, visiting the research and development section the rifle was tested with many others for compatibility.

The rifle just before it was fired. Sand was in every tiny crevasse.

Small Arms Defense Journal got a very rare and exclusive inside look at both Caracal and the actual performance of the Caracal CAR816 rifle. Chief Operating Officer Robert Hirt took the time out of his busy schedule to do a sand durability test on the rifle. Robert is one of the most respected design individuals in the industry. He was intimately involved with the Heckler & Koch 416 rifle program. The test rifle was pulled from the production line. The rifle was lubricated generously on the bolt carrier, bolt and inside of the upper receiver.

The rifle was function fired with a thirty round magazine. The ammunition being used was also quite interesting. The M855 ball ammunition is manufactured in the same building complex as the rifle. Caracal Light Ammunition is one of the only locally run munitions factories in the entire Gulf region. The actual projectiles are manufactured for 9mm and 5.56mm ammunition by Caracal Light Ammunition. They buy copper cups and raw lead. They draw the projectile, fill them with lead and in the case of the M855 the make the lead plugs and assemble the drawn jacket, penetrator core and lead plug. Cartridge cases come in as brass cups for both 9mm and 5.56mm and the entire cartridge case is made in-house. The primers and powder are not made in the UAE, they are purchased elsewhere. They use ultra modern loading equipment and are up to par with any western military grade ammunition manufacturer in production capability as well as quality control. Unfortunately, this ammunition is not available in the West.

After the rifle was tested, a new magazine was inserted and a round loaded in the chamber. We went out into the 115°F steaming desert. Robert dropped the rifle in a mound of sand on its left side with the ejection port cover closed. Then he continued to drag the rifle through the sand, cover the rifle so it could not be seen in that powder sand. Then he flipped the rifle over and did the same. To add to even more authenticity, Robert took one for the team and commenced a 20 or so foot low crawl in the burning hot sand. Robert got up, smacked the rifle a few times on both sides. We walked into the research and development range. He placed the rifle on semi-automatic and fired off 10 rounds with no malfunctions. You could clearly see sand/dust flying out of the rifle almost as if every time the rifle fired it cleaned sand out of its action. Robert then placed the rifle on automatic and fired the remaining 20 rounds with one long burst. Not a single malfunction. The rifle was “cold” and the cyclic rate was around 750 to 800 rounds per minute. Robert then handed the rifle to me and I continued to put 4 magazines through the rifle without lubrication or cleaning. There were others who shot another four or five magazines without any malfunctions. Once the rifle got hot the cyclic rate increased slightly but never exceeded 900 rounds per minute. According to Caracal the rifle is designed to handle cyclic rates up to 1,200 rounds per minute. This author has witnessed this same test with standard M4 rifles and I have to say I never saw a direct gas rifle make it through a test like this. This is the real environment this rifle is to operate in and one which is the worst environment you can put small arms in. Or any mechanism with moving parts for that matter. The test was not over. Robert took the rifle to the research and development department where he tore the rifle down. Soaked and swooshed the upper and lower in a 55 gallon drum of water. He did the same with the bolt carrier group. He then took a compressed air hose and dried all the components off. He put a generous amount of lubricant on the inside of the upper receiver and bolt carrier group and put the rifle back together. He inserted a clean 30 round magazine into the rifle and chambered a round. Then this he cut a ditch in the sand with his boot heel and threw the rifle in and once more doused both sides with sand. The only difference was this time he left the ejection port cover open, exposing the bolt carrier and surrounding area to the pesky powder sand. Once again he took that painfully hot low crawl through the sand to ensure the rifle was thoroughly covered. I really felt sorry for Robert, it really looked like a painful crawl and I felt worse he did this for my benefit! Robert got up, smacked the rifle on the sides a few times and walked into the range. Flipped the selector to semi-automatic and fired 10 rounds with no malfunctions. Then placed it on automatic and finished the following 20 rounds with no issues. The rifle was passed around and additional 8 or so magazines were fired on mostly fully automatic fire. The rifle never hiccupped once. Due to the limited 25 yard indoor range we were unable to do any accuracy testing. You would think there would be no lack of shooting spots in the middle of the desert. However laws in the UAE on transporting and use of firearms are very restrictive. We were unable to get the clearance in short notice for the outdoor ranges. Giving it was 115°F with blowing sand, I was not that disappointed.

The rifle being fired immediately after being pulled out of the sand by Caracal COO Robert Hirt. The first 10 rounds were fired on semi-automatic and then the rifle was placed on automatic fire and the remaining 20 rounds fired. There were no malfunctions of any sort. After the initial magazine, an additional 8 full 30-round magazines were fired without cleaning. The rifle experienced not a single stoppage. This author has seen M4 carbines fail this test on a regular basis. This was a tremendous testament to the durability and reliability of this rifle in the most unforgiving environment on the planet.

This test demonstrated a lot. Many who have followed Dust Test Three saw the numerous malfunctions the M4, HK416, FN SCAR and the XM8. The methods and conclusions of this test were questionable to say the least. They tried to duplicate desert conditions. Well, this test witnessed by SADJ was not an attempt to recreate anything but a real test in the real environment. This was real sand/moon dust and not a synthetic substitute. It was not just sand blowing in the rifle in a chamber but the rifle was covered, dragged and sand was smashed into every crevasse. This rifle shot without malfunction. What all this says is the military sales market in the Middle East is about to have a newcomer to the game and it is for sure to be an important one. This rifle will compete with the best the United States and Europe have to offer. This rifle is also made in the region where Caracal will be able to provide uninterrupted production, shipping, spare parts, technical assistance and work with customers on refinements per their needs. There is no doubt this rifle is for real. It was developed my some of the finest minds in the industry and backed by a company that will spare no expense to build the finest rifle they possibly can. The CEO, Hamad Salem Al Ameri is a soldier (Officer) in the UAE Army. He fully understands the consequences of a small arm failing in combat. To him there is no business decision or profit making changes that will compromise the soldier’s

life that carries his gun.

by Christopher R. Bartocci on 2 September, 2016.

http://www.sadefensejournal.com/wp/the-caracal-car816-the-new-desert-assault-rifle/