Neil

Senior Member

- Joined

- Jun 23, 2010

- Messages

- 2,818

- Likes

- 3,546

The most significant setback to production of MBT Arjun was the change in requirements put forth by the Army in February 2007. The tanks produced by HVF, Avadi were to be issued to the Army after inspection at the factory site in the Joint Receipt Inspection by the representatives of HVF, DRDO and Army. The issued tanks were put through two trials - the Field Trial and the Accelerated usage-cum-reliability trials (AUCRT), by the Army. Joint Receipt Inspection was conducted (March 2005) for first five MBT Arjun manufactured (2003-04) in the pilot phase, one year after production. The inspection of the second lot of nine pilot MBT Arjun, took place in February 2007, two years after production. By 2007, 53 MBT had already been produced by HVF, Avadi. It was during this inspection in February 2007 that Army reported water ingress in the fighting compartment of tank while crossing shallow parts of a river and raised two additional requirements in the design of the MBT Arjun viz. zero level ingress of water in the fighting compartment and lead time for fording (time from tank's entry into water to exit from water) to be minimised to 30 minutes.

We noticed that the corresponding benchmark fixed by the Army for T-90 tank was more relaxed, allowing 2.5 litres of water ingress. The requirement of zero level water ingress for medium fording was not stipulated in the Army's requirements (GSQR of 1985) or in subsequent stages of development which had seen many changes in design. In fact, the Joint Action Plan (of Army and DRDO), in August 1999, had cleared the medium fording capability of MBT Arjun. This issue was also not raised in the Joint Receipt Inspection of the first batch of pilot MBT Arjun. The new requirements necessitated the DRDO to modify the design of the second lot of nine pilot MBT Arjun. The same got modified and were issued to Army by September 2007. The first lot of five pilot tanks was brought back from Army, got modified and issued to Army till October 2007. Balance 39 tanks of the bulk production were dismantled, reworked and issued to the Army in 2008-10. The whole task of dismantling and reassembly of 53 MBTs entailed an additional cost of Rs 84 lakh. The Ministry stated (May 2014) that modifications were considered essential to improve overall performance from user's perspective. The reply undermines the impact of the modifications in derailing the production and issue of MBT Arjun, which was a significant factor that led to an import of T-90 tanks that cost Rs 4,913 crore in November 2007 as discussed in Paragraph 8.3.4. The reply also does not address why the benchmarks on MBT Arjun regarding water ingress and fording, were more stringent than the corresponding requirements on T-90 tank.

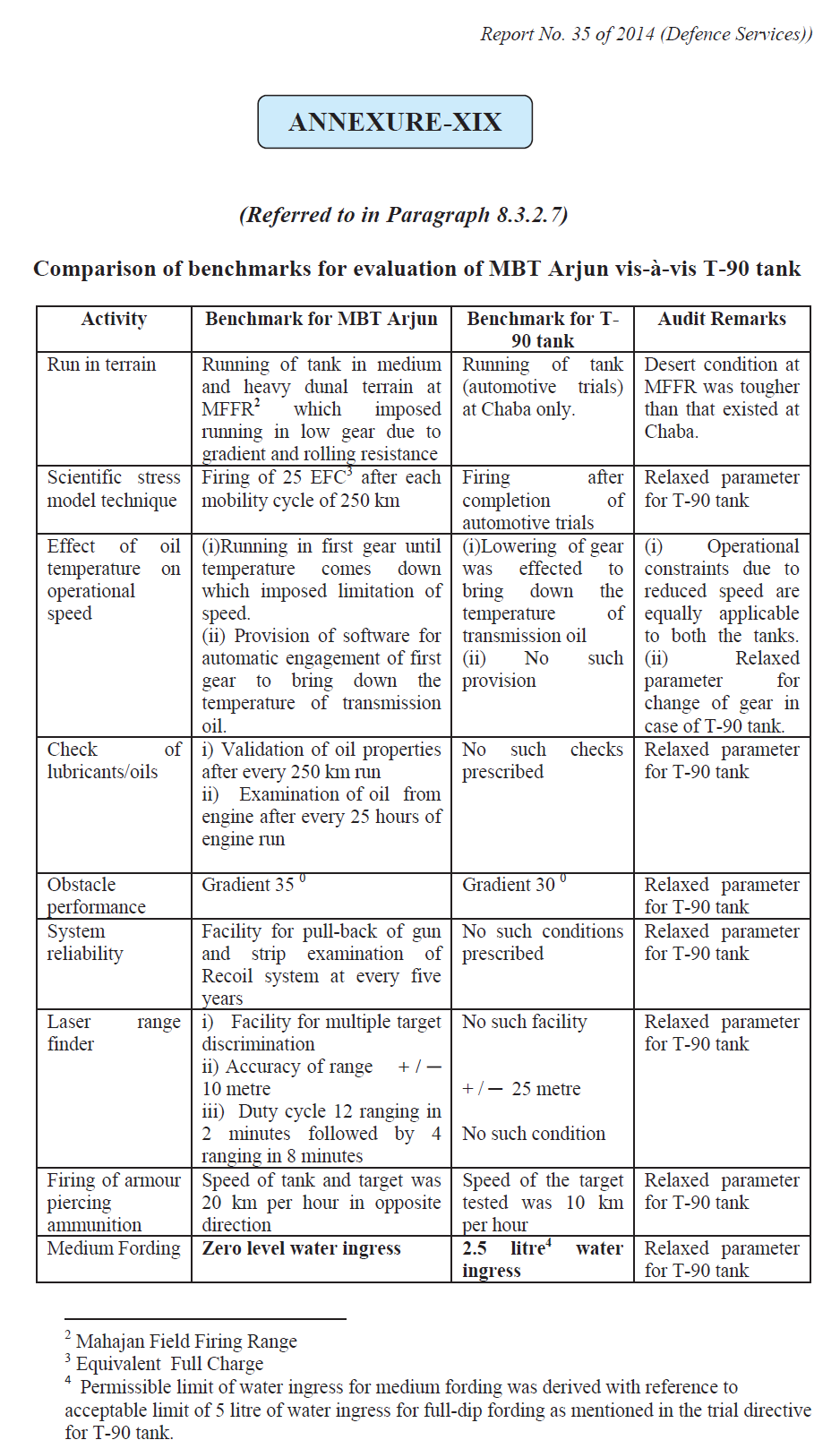

Medium fording was one of the eight instances we noticed, where Army placed benchmark of parameters on MBT Arjun which were more stringent in comparison to those placed on T-90 tanks. These are detailed in Annexure XIX. We could not assess the impact of these benchmarks on the performance of the two tanks from our scrutiny of the Report on comparative trials of MBT Arjun and T-90 tank (February/ March 2010- referred to in Paragraph 8.3.2.8 ). While we appreciate the Army's quest for improving the quality of MBT Arjun, the imposition of more stringent parameters precluded a level playing field and more importantly, the inability to freeze the designs led to several changes in design, consequent delays in acceptance of MBT Arjun by the Army and in the overall, the production and issue of MBT Arjun.

___________________________

IMPACT OF 'EVOLVING' GSQRs

___________________________

Changes in design

Mention was made in Report No. 3 of 2006 of the Comptroller and Auditor General of India about the frequent changes in design leading to delay in development of MBT Arjun. The development of MBT prototype was to be completed by April 1982 but after going through several modifications in design, the prototype was cleared by the Army in 1998. Given this concern on several changes in design, the Scientific Advisor to the Raksha Mantri had confirmed (2004) in a note to the Ministry that the design for MBT stood frozen. This was, however, not the case. We found that 316 amendments to design of various assemblies were carried out even after freezing of the design and up to August 2010. The changes were mostly justified by the Ministry in its reply (May 2014) as necessitated for product improvement and modifications based on user's feedback on quality problems. The reply does not take cognizance of the fact that even after clearing the production after acceptance of the prototype (1998), the designs continued to be re-worked for 12 years thereafter and frozen only in 2010.

_________________________________

ARJUN - T-90 COMPARATIVE TRIALS

_________________________________

Comparative field trials of MBT Arjun with T-90 tanks took place in February/ March 2010. Till such time, the Army had been consistently reporting quality problems in MBT Arjun; this was also reported to the Standing Committee on Defence (2007-08). The comparative trials were on four parameters viz. fire power, survivability, reliability and miscellaneous issues of the tank with weightage of 40, 35, 15 and 10 respectively. As per the trial report, MBT Arjun performed marginally better than the T-90 tank in accuracy and consistency of firepower. However, T-90 tank performed better in lethality and missile firing capability. The Army concluded (April 2010) that "Arjun had performed creditably and it could be employed both for offensive and defensive tasks with same efficacy of T-90 tank." The Army also recommended upgrades to make the Arjun tank a superior weapon platform. We were informed (February 2014) that the Mark-II version of MBT Arjun was under trials by the Army and that it would include the upgrades recommended by the Army.

We found that the MBT Arjun and T-90 tank were not exactly comparable in missile firing ability; the higher score of T-90 tank was mainly due to missile firing ability which was not in the design of MBT Arjun. Barring missile firing ability, the scores of MBT Arjun and T-90 tank would be 25.77 and 24.50 respectively in firepower. In the overall comparative score, T-90 tank scored 75.01, marginally higher than MBT Arjun which scored 72.46, mainly because of higher score on missile firing ability of T-90 tank.

__________________

T-90 PRODUCTION

__________________

The Russian Firm, M/s Rosoboronexport (ROE) was expected to transfer the design details in the Transfer-of-Technology (ToT) documents by March 2003. The documents were in Russian; the Army/Ordnance Factories' efforts to get translated documents from ROE, failed. The documents were received between September 2001 and January 2003 following which HVF, Avadi concluded four contracts between September 2003 and September 2006 for translation of the documents. The translation was completed by July 2007 after the expiry of scheduled delivery period of first batch of 50 indigenous tanks by 2006-07. In all, the translation of ToT documents took almost six years.

The Ministry stated (May 2014) that translation of critical documents for indigenous manufacturing was carried out with available resource of Russian translators at HVF and there was no delay in production due to pending translation. The reply is not acceptable because delay in translation of ToT documents had certainly impacted on the indigenous production of T-90 tanks as production could not commence without the availability of translated documents.

Non-receipt of design documents for critical assemblies

We found that ToT documents in respect of some critical assemblies were not transferred by the Russian manufacturer, ROE, even after lapse of 12 years as of July 2013. An important component was the gun system (including barrel) for which the design had not been received as of May 2014. In fact, the Ministry cited this issue as the main reason for slippage in indigenous production of T-90 tank.

________________________________

QUALITY PROBLEMS WITH THE T-90

________________________________

During March 2010 to November 2013, HVF received 45 defect reports (DRs) from the Army relating to minor and major defects in the indigenous T-90 tanks. The defects mainly pertained to failure of gear box and defects in auto/electrical portion of the tanks. A Working Group was proposed (March 2012) to address these deficiencies which was not formed. The HVF, Avadi constituted (November 2004) a Failure Review Board (FRB) at factory level to investigate the reasons for defects at the users end. The FRB discussed (September 2013) the major failures and recommended remedial measures.

Accordingly, HVF implemented:

"¢ a process audit to eliminate non-conformances in assembling process;

"¢ introduction of 100 per cent pre-fitment and component level inspection and additional quality assurance checks at local supplier's premises;

"¢ extensive trials of samples supplied by the local firms after introducing improvements and before their induction into regular production; and

"¢ deputing of HVF's teams to field locations to ensure technical and maintenance support to the users.

Ministry told us that the FRB was a quality tool which facilitated timely action on defects. The delay in discussion of the FRB (September 2013), even when

the Army was raising quality concerns since March 2010, was not however, commented upon by the Ministry.

___________________

PRODUCTION RATE

___________________

Arjun:

The Public Accounts Committee had urged (December 2003) the Ministry to utilize the infrastructural facilities optimally so that the desired volume of production of MBT Arjun would enable increase of the indigenous content to 55 per cent. The Ministry assured the Committee that a production level, initially of 300 MBT Arjun to be raised to 500 tank later, would reduce the import content to under 30 per cent.

However, barring the initial indent of 124 tanks, the Board did not receive any further indents for MBT Arjun. Production has come to standstill since 2009-10 and to that extent, capacity created at a cost of Rs 87 crore for annual production of 30 MBT Arjun awaits utilization against Ministry's decision for fresh orders. Meanwhile, HVF, Avadi holds idle inventory of Rs 128 crore reflected as "Work-in-progress", which remains unutilised in the absence of fresh orders. The cost per MBT Arjun was Rs 21 crore (2009-10), against which the import content was Rs 13 crore. This brings the level of indigenisation in MBT Arjun to 38 per cent only. The initial development project on MBT Arjun had envisaged that barring the engine, all components/assemblies would be indigenously produced. Problems in sourcing major assemblies other than engines have been discussed in Paragraph 8.3.2.6.

T-90:

The production of T-90 tank at HVF, Avadi was short of the indent of November 2004 for 300 tanks, by 75 tanks as of March 2013. Even as the production was underway against the first indent, the Army placed a second indent for 236 T-90 tanks in December 2013. Meanwhile, the Ministry sanctioned (September 2011) Rs 971 crore for capacity augmentation of T-90 tank production by March 2014. This was expected to raise the capacity of Ordnance Factories from 100 per cent to 140 per cent of T-90 tanks.

It is noteworthy that Rs 96 crore was sanctioned (February 2004) for creating production capacity for 100 T-90 tanks, whereas augmentation of capacity from 100 to 140 tanks is slated for Rs 971 crore, a ten times increase in estimation over a period of seven years. Reasons for the extraordinary increase were not provided by the Ministry, in its response of May 2014. As of March 2014, only an amount of Rs 17 crore had been spent on the augmentation project and in the revised schedule, the project is expected to be completed in December 2016. The Board appears to have put the augmentation plan on a slow track as of now.

Report no-35 of 2014

P.S: the report has been sourced from BR posted by Viv S

We noticed that the corresponding benchmark fixed by the Army for T-90 tank was more relaxed, allowing 2.5 litres of water ingress. The requirement of zero level water ingress for medium fording was not stipulated in the Army's requirements (GSQR of 1985) or in subsequent stages of development which had seen many changes in design. In fact, the Joint Action Plan (of Army and DRDO), in August 1999, had cleared the medium fording capability of MBT Arjun. This issue was also not raised in the Joint Receipt Inspection of the first batch of pilot MBT Arjun. The new requirements necessitated the DRDO to modify the design of the second lot of nine pilot MBT Arjun. The same got modified and were issued to Army by September 2007. The first lot of five pilot tanks was brought back from Army, got modified and issued to Army till October 2007. Balance 39 tanks of the bulk production were dismantled, reworked and issued to the Army in 2008-10. The whole task of dismantling and reassembly of 53 MBTs entailed an additional cost of Rs 84 lakh. The Ministry stated (May 2014) that modifications were considered essential to improve overall performance from user's perspective. The reply undermines the impact of the modifications in derailing the production and issue of MBT Arjun, which was a significant factor that led to an import of T-90 tanks that cost Rs 4,913 crore in November 2007 as discussed in Paragraph 8.3.4. The reply also does not address why the benchmarks on MBT Arjun regarding water ingress and fording, were more stringent than the corresponding requirements on T-90 tank.

Medium fording was one of the eight instances we noticed, where Army placed benchmark of parameters on MBT Arjun which were more stringent in comparison to those placed on T-90 tanks. These are detailed in Annexure XIX. We could not assess the impact of these benchmarks on the performance of the two tanks from our scrutiny of the Report on comparative trials of MBT Arjun and T-90 tank (February/ March 2010- referred to in Paragraph 8.3.2.8 ). While we appreciate the Army's quest for improving the quality of MBT Arjun, the imposition of more stringent parameters precluded a level playing field and more importantly, the inability to freeze the designs led to several changes in design, consequent delays in acceptance of MBT Arjun by the Army and in the overall, the production and issue of MBT Arjun.

___________________________

IMPACT OF 'EVOLVING' GSQRs

___________________________

Changes in design

Mention was made in Report No. 3 of 2006 of the Comptroller and Auditor General of India about the frequent changes in design leading to delay in development of MBT Arjun. The development of MBT prototype was to be completed by April 1982 but after going through several modifications in design, the prototype was cleared by the Army in 1998. Given this concern on several changes in design, the Scientific Advisor to the Raksha Mantri had confirmed (2004) in a note to the Ministry that the design for MBT stood frozen. This was, however, not the case. We found that 316 amendments to design of various assemblies were carried out even after freezing of the design and up to August 2010. The changes were mostly justified by the Ministry in its reply (May 2014) as necessitated for product improvement and modifications based on user's feedback on quality problems. The reply does not take cognizance of the fact that even after clearing the production after acceptance of the prototype (1998), the designs continued to be re-worked for 12 years thereafter and frozen only in 2010.

_________________________________

ARJUN - T-90 COMPARATIVE TRIALS

_________________________________

Comparative field trials of MBT Arjun with T-90 tanks took place in February/ March 2010. Till such time, the Army had been consistently reporting quality problems in MBT Arjun; this was also reported to the Standing Committee on Defence (2007-08). The comparative trials were on four parameters viz. fire power, survivability, reliability and miscellaneous issues of the tank with weightage of 40, 35, 15 and 10 respectively. As per the trial report, MBT Arjun performed marginally better than the T-90 tank in accuracy and consistency of firepower. However, T-90 tank performed better in lethality and missile firing capability. The Army concluded (April 2010) that "Arjun had performed creditably and it could be employed both for offensive and defensive tasks with same efficacy of T-90 tank." The Army also recommended upgrades to make the Arjun tank a superior weapon platform. We were informed (February 2014) that the Mark-II version of MBT Arjun was under trials by the Army and that it would include the upgrades recommended by the Army.

We found that the MBT Arjun and T-90 tank were not exactly comparable in missile firing ability; the higher score of T-90 tank was mainly due to missile firing ability which was not in the design of MBT Arjun. Barring missile firing ability, the scores of MBT Arjun and T-90 tank would be 25.77 and 24.50 respectively in firepower. In the overall comparative score, T-90 tank scored 75.01, marginally higher than MBT Arjun which scored 72.46, mainly because of higher score on missile firing ability of T-90 tank.

__________________

T-90 PRODUCTION

__________________

The Russian Firm, M/s Rosoboronexport (ROE) was expected to transfer the design details in the Transfer-of-Technology (ToT) documents by March 2003. The documents were in Russian; the Army/Ordnance Factories' efforts to get translated documents from ROE, failed. The documents were received between September 2001 and January 2003 following which HVF, Avadi concluded four contracts between September 2003 and September 2006 for translation of the documents. The translation was completed by July 2007 after the expiry of scheduled delivery period of first batch of 50 indigenous tanks by 2006-07. In all, the translation of ToT documents took almost six years.

The Ministry stated (May 2014) that translation of critical documents for indigenous manufacturing was carried out with available resource of Russian translators at HVF and there was no delay in production due to pending translation. The reply is not acceptable because delay in translation of ToT documents had certainly impacted on the indigenous production of T-90 tanks as production could not commence without the availability of translated documents.

Non-receipt of design documents for critical assemblies

We found that ToT documents in respect of some critical assemblies were not transferred by the Russian manufacturer, ROE, even after lapse of 12 years as of July 2013. An important component was the gun system (including barrel) for which the design had not been received as of May 2014. In fact, the Ministry cited this issue as the main reason for slippage in indigenous production of T-90 tank.

________________________________

QUALITY PROBLEMS WITH THE T-90

________________________________

During March 2010 to November 2013, HVF received 45 defect reports (DRs) from the Army relating to minor and major defects in the indigenous T-90 tanks. The defects mainly pertained to failure of gear box and defects in auto/electrical portion of the tanks. A Working Group was proposed (March 2012) to address these deficiencies which was not formed. The HVF, Avadi constituted (November 2004) a Failure Review Board (FRB) at factory level to investigate the reasons for defects at the users end. The FRB discussed (September 2013) the major failures and recommended remedial measures.

Accordingly, HVF implemented:

"¢ a process audit to eliminate non-conformances in assembling process;

"¢ introduction of 100 per cent pre-fitment and component level inspection and additional quality assurance checks at local supplier's premises;

"¢ extensive trials of samples supplied by the local firms after introducing improvements and before their induction into regular production; and

"¢ deputing of HVF's teams to field locations to ensure technical and maintenance support to the users.

Ministry told us that the FRB was a quality tool which facilitated timely action on defects. The delay in discussion of the FRB (September 2013), even when

the Army was raising quality concerns since March 2010, was not however, commented upon by the Ministry.

___________________

PRODUCTION RATE

___________________

Arjun:

The Public Accounts Committee had urged (December 2003) the Ministry to utilize the infrastructural facilities optimally so that the desired volume of production of MBT Arjun would enable increase of the indigenous content to 55 per cent. The Ministry assured the Committee that a production level, initially of 300 MBT Arjun to be raised to 500 tank later, would reduce the import content to under 30 per cent.

However, barring the initial indent of 124 tanks, the Board did not receive any further indents for MBT Arjun. Production has come to standstill since 2009-10 and to that extent, capacity created at a cost of Rs 87 crore for annual production of 30 MBT Arjun awaits utilization against Ministry's decision for fresh orders. Meanwhile, HVF, Avadi holds idle inventory of Rs 128 crore reflected as "Work-in-progress", which remains unutilised in the absence of fresh orders. The cost per MBT Arjun was Rs 21 crore (2009-10), against which the import content was Rs 13 crore. This brings the level of indigenisation in MBT Arjun to 38 per cent only. The initial development project on MBT Arjun had envisaged that barring the engine, all components/assemblies would be indigenously produced. Problems in sourcing major assemblies other than engines have been discussed in Paragraph 8.3.2.6.

T-90:

The production of T-90 tank at HVF, Avadi was short of the indent of November 2004 for 300 tanks, by 75 tanks as of March 2013. Even as the production was underway against the first indent, the Army placed a second indent for 236 T-90 tanks in December 2013. Meanwhile, the Ministry sanctioned (September 2011) Rs 971 crore for capacity augmentation of T-90 tank production by March 2014. This was expected to raise the capacity of Ordnance Factories from 100 per cent to 140 per cent of T-90 tanks.

It is noteworthy that Rs 96 crore was sanctioned (February 2004) for creating production capacity for 100 T-90 tanks, whereas augmentation of capacity from 100 to 140 tanks is slated for Rs 971 crore, a ten times increase in estimation over a period of seven years. Reasons for the extraordinary increase were not provided by the Ministry, in its response of May 2014. As of March 2014, only an amount of Rs 17 crore had been spent on the augmentation project and in the revised schedule, the project is expected to be completed in December 2016. The Board appears to have put the augmentation plan on a slow track as of now.

Report no-35 of 2014

P.S: the report has been sourced from BR posted by Viv S