Trainers

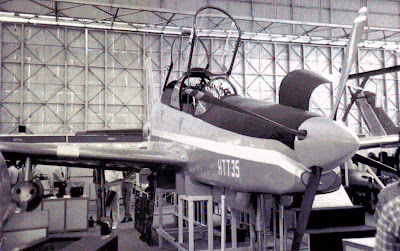

The two above photos graphically illustrate both the missed opportunities as well as the challenges now confronting Hindustan Aeronautics Ltd (HAL) to deliver the new-generation HTT-40 advanced turboprop trainer to the Indian Air Force (IAF). The first photo is that of the long-forgotten HTT-35 advanced turboprop trainer, in particular its full-scale mock-up, which was designed and fabricated in-house by HAL in the late 1980s and rolled out in the early 1990s—all in all a four-year effort. The objective at that time was to team up with a global avionics supplier (most probably THALES) and co-design the semi-glass tandem cockpits and offer the aircraft for evaluation by the IAF by 1998. However, after 1994 the HTT-35 disappeared, literally! One can only speculate on what exactly happened to this full-scale mock-up, or on why did the MoD or IAF HQ develop a coordinated ‘memory loss’ on the need to series-produce the HTT-35. For it was realised as far back as 1998 that the induction of fourth-generation combat aircraft such as the Su-30MKI and the likely induction of additional medium multi-role combat aircraft (M-MRCA) and the fifth-generation fighter aircraft (FGFA) would force the IAF sooner than later into undertaking a critical revision of its flying training practices that included primary flying training, intermediate flying training, and lead-in fighter training (LIFT).

Each of these three stages requires a dedicated flying training aircraft, starting with benign turboprop trainers, followed by intermediate jet trainers (IJT), and culminating in LIFT aircraft, following which those destined to fly combat aircraft are assigned to a dedicated Operational Conversion Unit (OCU) to convert to a particular aircraft type by either training on tactical simulators for some 40 hours, or directly proceeding to gain flight experience for some 200 hours on the single/twin-seat operational combat aircraft. As a rule, therefore, air forces worldwide upgrade their fleets of flying training aircraft by first procuring advanced turboprop trainers, followed by intermediate or advanced jet trainers, and lastly, LIFT aircraft. For the IAF, however, this is not the way flying training is being or has been conducted for a number of reasons. Firstly, Air HQ has yet to induct a suitable turboprop trainer to replace its existing fleet of piston-engined HPT-32 Deepak primary trainers of 1980s vintage. Although HAL had in the mid-1990s done considerable R & D work on the HTT-35 tandem-seat turboprop training aircraft, such efforts, for mysterious reasons, could not culminate in the HTT-35 being put to series-production. Secondly, HAL has for the past two years been unable to accelerate R & D work on the indigenous tandem-seat HJT-36 IJT, work on which began in July 1999, but the first prototype aircraft was able to take to the air only on March 7, 2003. To make matters worse, it was only on March 9, 2006 that the Cabinet Committee on National Security approved the acquisition of the first 12 production-standard IJTs at a cost of Rs4,868.2 million, which means initial deliveries will only get underway by late 2019. Meanwhile, deliveries of all BAE Systems Hawk Mk132s will be concluded before even the first 12 HJT-36s start rolling out. This, consequently, will result in the IAF’s Training Command revising its LIFT syllabus first and the intermediate flying training curriculum later—a top-down approach—instead of undertaking a bottoms-up approach. What is likely to complicate matters even further is the IAF’s inability, till this day, to procure both cockpit procedure trainers and tactical flying training simulators for frontline combat aircraft like the upgraded MiG-21 Bison and the upgraded MiG-27Ms. It is another story that existing simulators for the HAL-built Jaguar IS/IM and Dassault Mirage 2000H/TH are in dire need of upgrades and refurbishment.

Given the accelerated induction of Su-30MKIs and the impending induction of new-generation M-MRCAs and FGFAs, it is therefore highly likely that the MoD will soon issue global RFPs for up to 60 new-generation turboprop training aircraft and the follow-on tranche of 57 LIFT aircraft. Simply put, LIFT encompasses the entire process of preparing aircrew to both fly and undertake flight/weapon systems management found on board fourth- and fifth-generation combat aircraft in the most effective way. The idea here is to utilise LIFT aircraft and its related tactical full-motion simulators in a way that replicates the flight control and management characteristics of those frontline combat aircraft that have cost-prohibitive direct operating costs per flight hour. Typically, a LIFT aircraft therefore is employed for imparting flying training in the following phases: transition, all-weather formation flying, combat manoeuvring, low-level navigation, ground attack orientation, cockpit systems management, mission planning, weapons delivery, and multi-mode radar operations. Though the Hawk Mk132 is often touted as having ‘morphed’ into a LIFT aircraft, it cannot yet be classified as a LIFT platform for the following reasons:

• A LIFT aircraft, in order to replicate the flight control characteristics of aircraft like the Su-30MKI, PAK-FA or MiG-29K, will be required to have a digital, quadruplex fly-by-wire (FBW) flight control system. The Hawk Mk132 does not have FBW flight controls.

• The LIFT aircraft must be supersonic and have a thrust-to-weight ratio between 0.7 and 1.0, against 0.45 for the Hawk Mk132, which is subsonic in flight.

• High angle-of-attack capability while maintaining full control, and possessing a multi-mode pulse-Doppler fire-control radar is a must for any LIFT aircraft. The Hawk Mk132 is found lacking in both these areas.

It is purely for these reasons that aircraft manufacturers like Aermacchi of Italy, Russia’s United Aircraft Corp and the joint venture of Lockheed Martin and Korea Aerospace Industries have developed new-generation supersonic LIFT aircraft like the M-346, Yak-130 and T-50 Golden Eagle. Aircraft like these have been optimised for imparting basic combat training, weapons employment training, and enhancing the aircrew’s on-board avionics-related systems handling/management skills. The secondary role of such LIFT aircraft in wartime could be both defensive counter-air as well as tactical interdiction missions. Given such realities, the options ahead for the IAF are three-fold:

• Revive the HTT-35 along with HAL (as the HTT-40) and equip the aircraft’s cockpits with AMLCD-based electronic flight instrumentation systems (see Photo 2 above) designed to enhance the trainee pilot’s aircraft handling and systems management skills.

• Accelerate the certification process of the single-engined HJT-36 IJT and upgrade its cockpits by installing AMLCD-based avionics and electronic flight instrumentation/management systems, all integrated by MIL-STD-1553B digital data bus.

In addition, a LIFT-specific mission planning system should be developed as an integral part of the LIFT curriculum. Such a system, replicating those of frontline combat aircraft, should enable rapid mission planning on the ground, with aircraft loading via a manportable data loader. The mission data loader should be fully compatible with all frontline operational ground-based training systems, and should also act as the data storage medium for mission recording automatically from power-on to shutdown. To enable full mission playback after flight, the system should record all display input data, with provision for event markers where required.